3D Printers

Filaments

Software

Printing Service

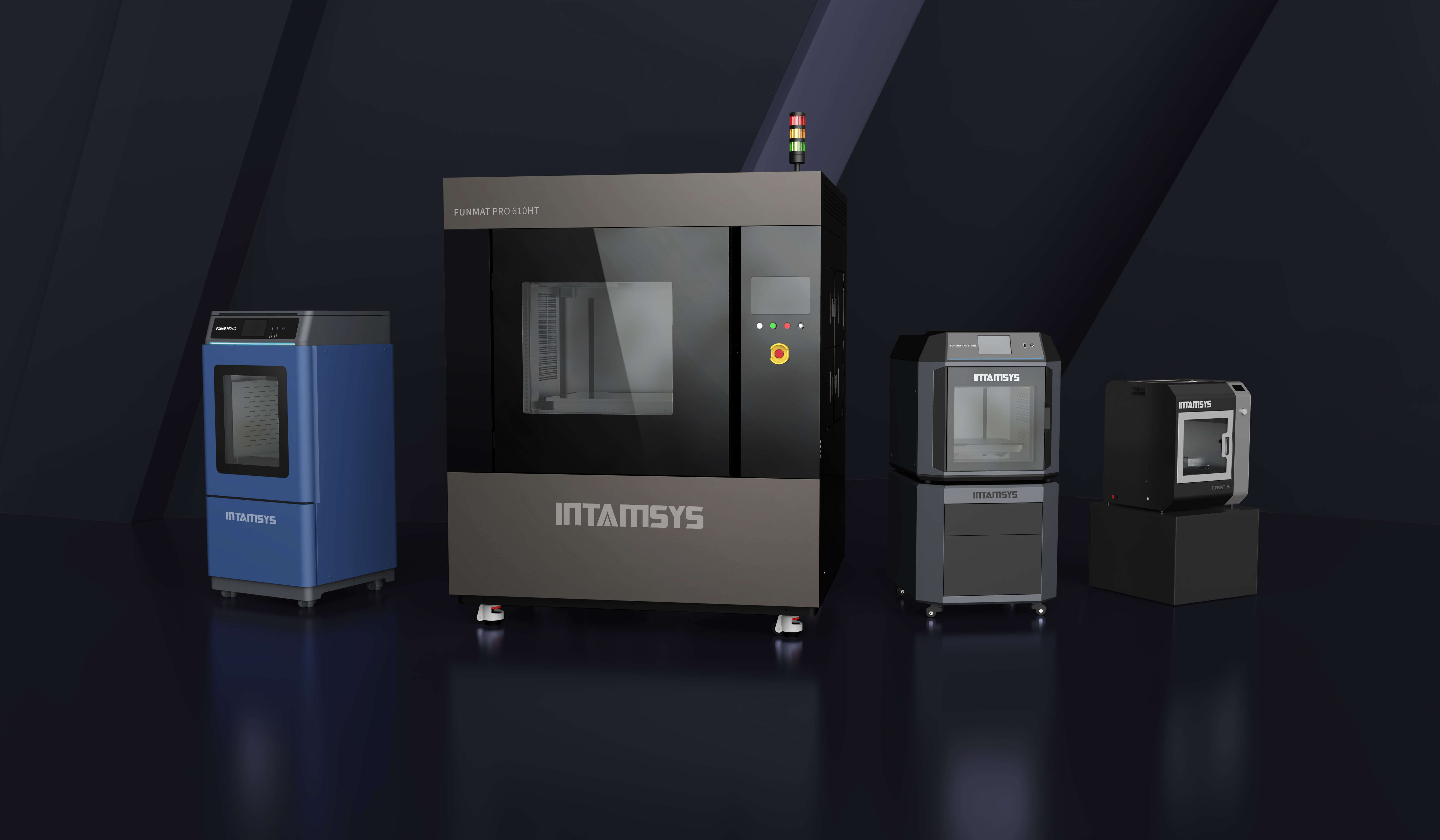

INTAMSYS offers advanced FFF 3D printers for high-performance and engineering-grade materials, providing exceptional precision and reliability for industries like aerospace, automotive, manufacturing and medical.

Explore More

Discover INTAM™ High-Performance, Engineering-grade, basic and support materials for FFF 3D printers.

Explore More

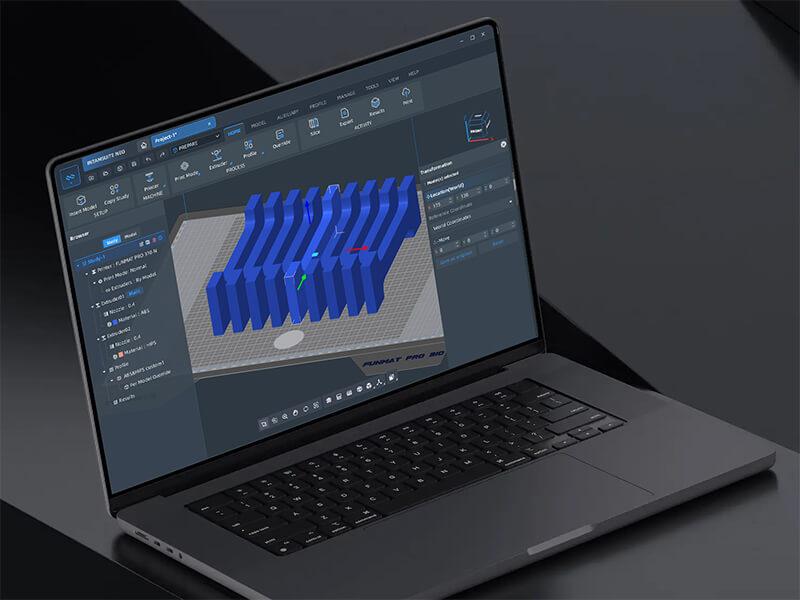

INTAMSUITE offers comprehensive 3D printing software solutions, from demand analysis to product delivery, enabling scalable additive production. The cloud platform and open APIs accelerate Industry 4.0 transition, ensuring data security and meeting diverse user needs.

Explore More

One on one expert consultation, capable of printing engineering and high-performance materials, ideal for direct manufacture end-use parts.

Explore More

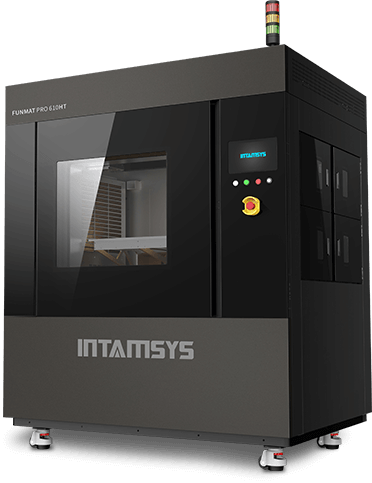

LARGE BUILD VOLUME INDUSTRIAL 3D PRINTER

Up to 300℃ Heated Chamber

Large-Format

Continuous Production

INDUSTRIAL HIGH-SPEED 3D PRINTER

Industrial Performance

High-Speed Printing

High Versatility

EXPLORE MORE

3D printing technology offers lightweight design, rapid manufacturing, and customized solutions for the aerospace industry, significantly reducing manufacturing costs for complex components and enhancing design efficiency.

INTAMSYS's large-format 3D printing solution for accelerating Automotive product development and innovative design

INTAMSYS' FFF 3D printing solutions empower manufacturing by offering versatile thermoplastic materials, unlimited design possibilities, and streamlined production.

3D printing for Medical enabling personalized treatments, advanced medical device manufacturing, and groundbreaking opportunities for medical research.

INTAMSYS' 3D printing solutions enhance vocational education by fostering creativity and problem-solving skills through hands-on experience.

INTAMSYS' 3D printing propels scientific research with innovative solutions, driving additive manufacturing, new material research, interdisciplinary synergy, and the application of advanced technologies.

Large-format, high performance material printing

Superior surface finish of complex geometries

High dimensional accuracy and enhanced mechanical properties

Industrial-grade consistency and reliable repeatability

High printing speed

Unattended operation with intelligent design

Additive manufacturing software platform for the production at scale

Continuous production 24/7

High reliability with minimized downtime

Open material system offers cost-effectiveness

EXPLORE MORE

Boosting manufacturing efficiency, ASMPT partners with INTAMSYS for high-tech 3D printing solutions. Discover how the FUNMAT PRO 310 NEO enhances semiconductor production.

Read More

Discover how eVTOL aircraft are transforming the future of transportation. Learn about their potential applications in urban air mobility, emergency response, and logistics, and explore how this innovative technology is driving sustainability in aviation.

Read More

Discover how the INTAMSYS FUNMAT PRO 610 HT and high-performance polymers are revolutionizing the design and manufacturing of lightweight, high-strength humanoid robots.

Read More

CNES leverages INTAMSYS 3D printers innovatively in satellite assembly, showcasing the efficiency and capabilities of additive manufacturing in the space industry.

Read More

Explore how Rennteam University of Stuttgart leverages INTAMSYS's advanced 3D printing solutions to revolutionize their Formula Student electric and autonomous racing cars.

Read More

We have successfully partnered with JLC, a leading player in the electronics industry, to break new ground in the field of large-size 3D printing services.

Read More

Or contact us via email: info@intamsys.com