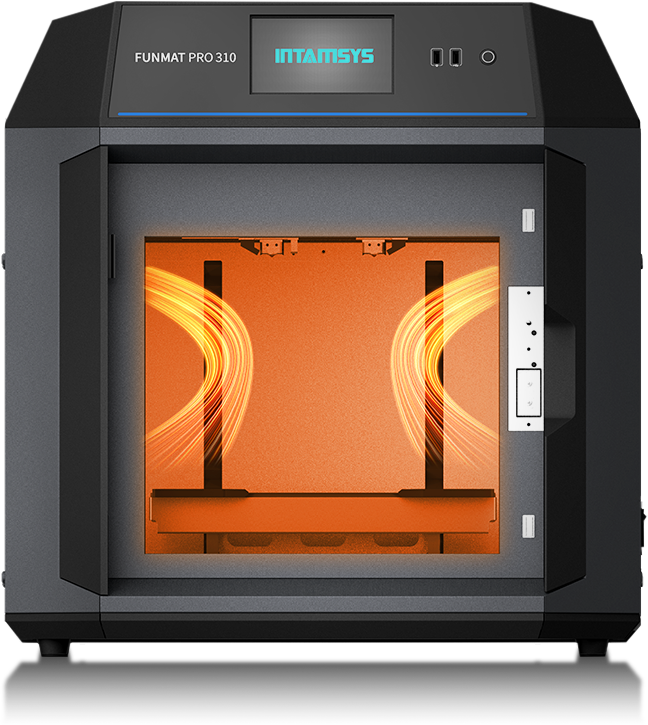

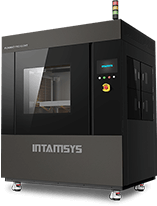

FUNMAT PRO 310

BRING INDUSTRIAL PERFORMANCETO YOUR DESKTOP

Watch Video

A Staple of Industrial Manufacturing: Print Multiple Engineering Materials

By Bringing Industrial Performance to Desktop 3D Printing Enabling

Additive Manufacturing to Empower More Innovators

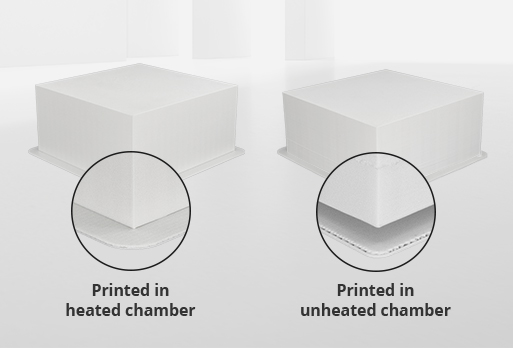

Superior 100°C Thermostatic Chamber for

Enhanced Mechanical Properties of Printed Parts

Actively heated thermostatic build chamber with temperatures up to 100°C, ensuring low internal stresses and good interlayer bonding of parts. Provide better mechanical properties and suitable for printing all types of engineering plastics.

Reduce thermal deformation and shrinkage of the model during the printing process, avoiding warping to achieve large-format (305 x 260 x 260 mm) printing.

The engineering material PC is significantly affected by temperature during the printing process. When the length of one edge exceeds 150 mm, a constantly heated chamber at 100°C can avoid warping, delamination, cracking, deformation, and other issues with the printed part.

Based on insights into material properties and the optimization of the printing process, the best performance of the material can be achieved. This can improve the Z-direction tensile strength of the printed parts.

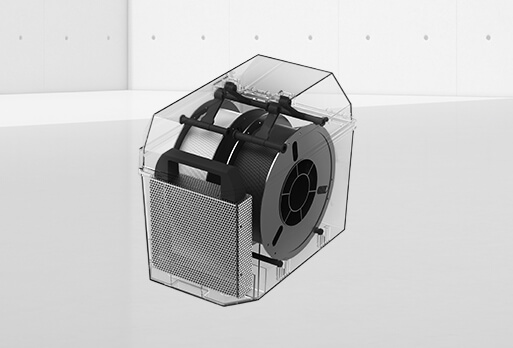

INTAM™ Box with Reusable Molecular Sieve to Keep Filament Dry

Ensures Optimal Printing Conditions for the Materials

Standard independent sealed keep-dry chamber with reusable molecular sieve. Its active moisture absorption function maintains long-term low humidity, eliminating the need to repeatedly dry the filaments.

The anti-tangle design avoids tangling and knotting of filament to ensure continuous printing.

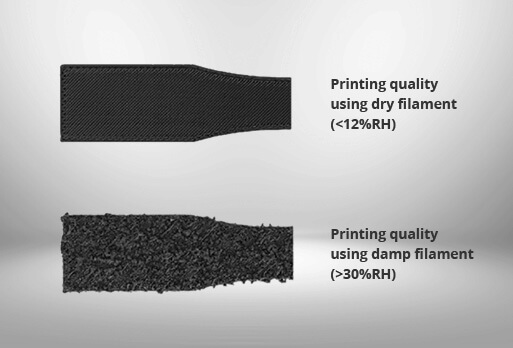

Compared with damp filament, printing with dry filament may avoid warping, bubbles, and burrs, ensuring continuous high-quality printing of moisture-absorbent materials like Nylon (PA, PA-CF) and others.

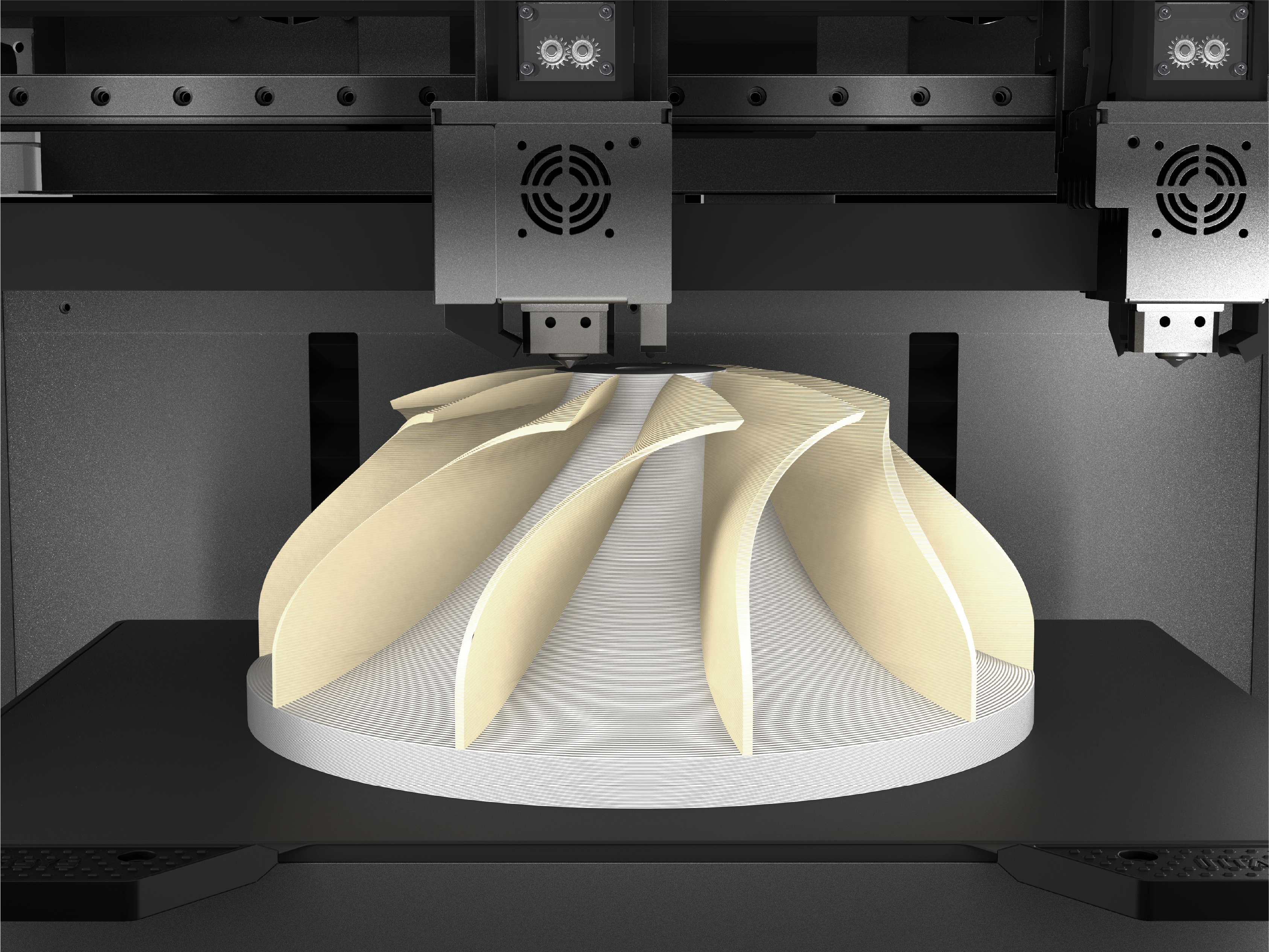

Ensure High-Quality Surface Finish of Printed Parts in ABS/PC/PC-ABS/PA/PA-CF and Other Engineering Materials

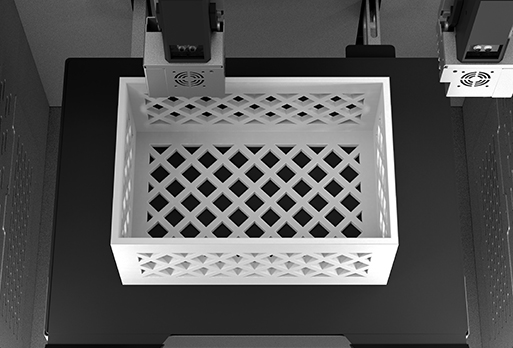

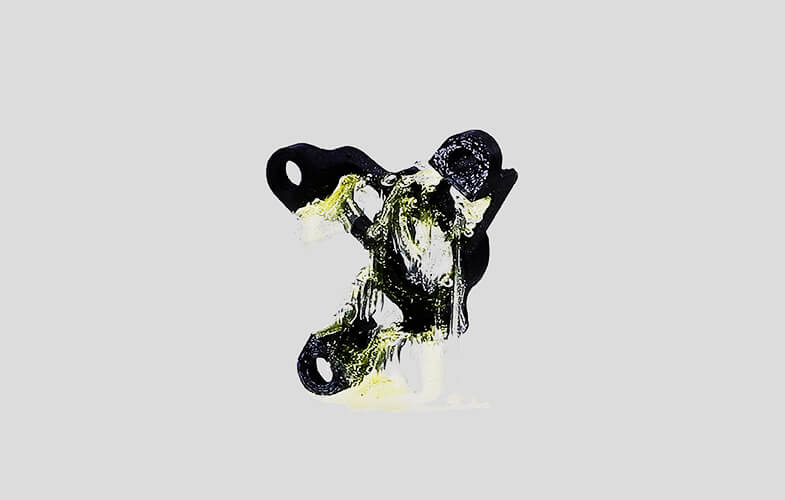

Two printheads can independently operate along the same axis during the printing process,

ensuring the printing quality of complex geometry parts in conjunction with the engineering material support solution.

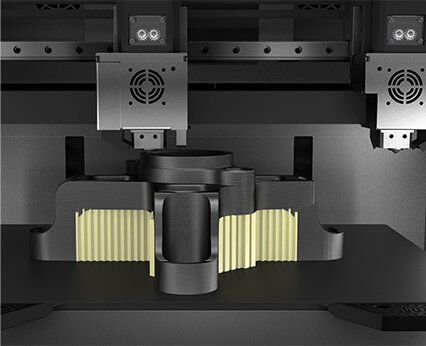

When printing complex geometries such as piping, where manually removing support material is challenging, water-soluble materials can be used. These materials support the structure during printing and dissolve in water afterward, ensuring perfect printing quality.

The dual extruder design makes it easy to remove support material without worrying about the roughness of the contact surface caused by peeling.

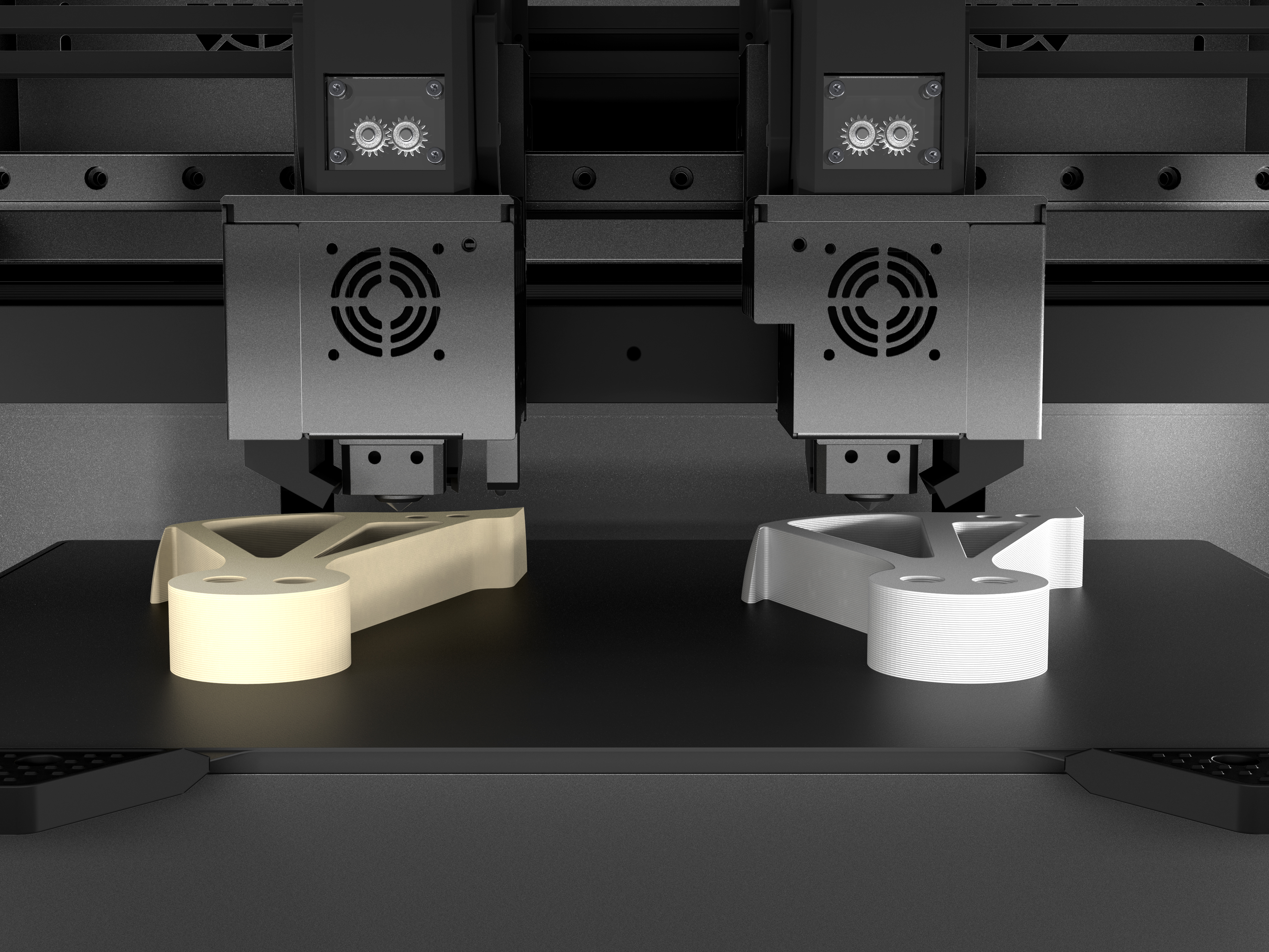

Mirror/Copy Mode

For Improved Batch Printing Efficiency

Support Mode Printing Enables

High-Quality Finish Complex Geometries Printing

Accuracy of Printed Parts

Dual Color Printing Brings More Design Inspiration

FUNMAT PRO 310 Provides a Good Experience for 3D Printing Beginners and Experts Alike

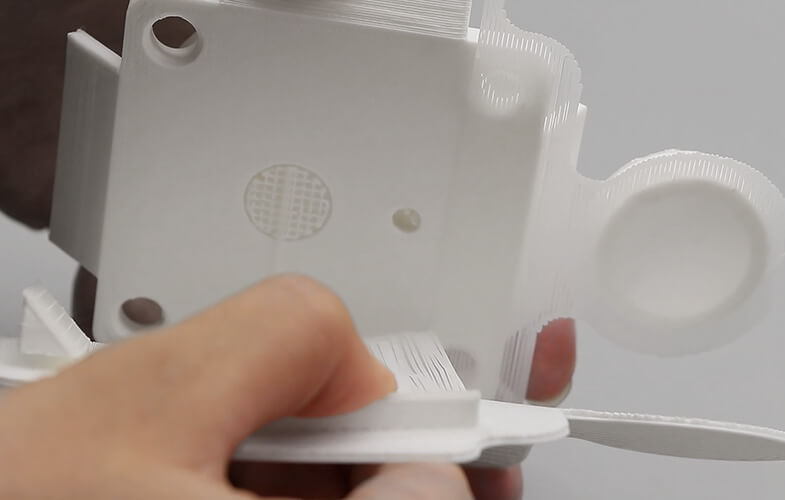

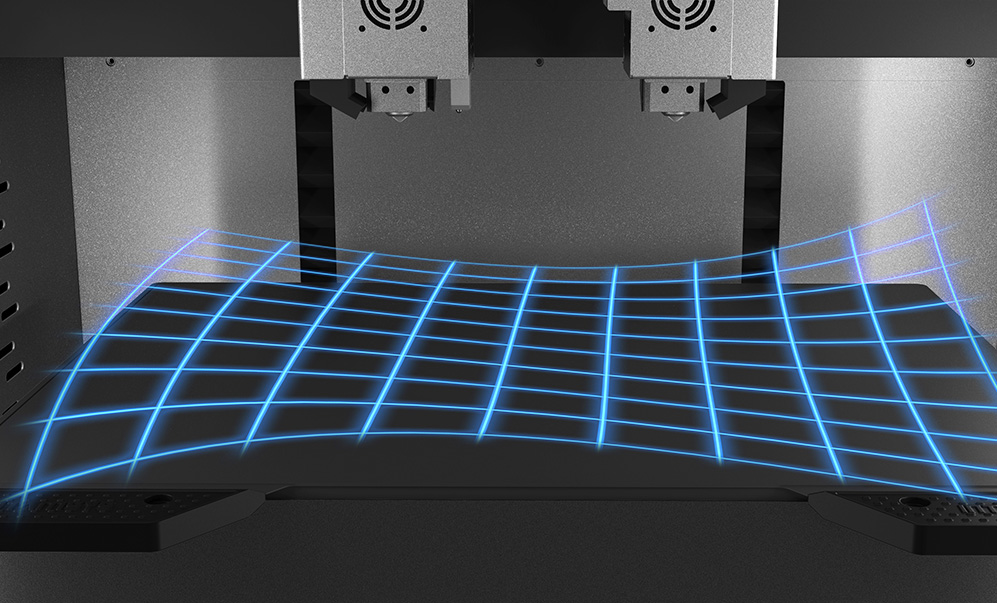

Auto mesh leveling with 100-point surface flatness measurement and automatic Z-axis compensation. Flexible build plate for easy part removal with glue-free bed adhesion.

Intelligent interactive design with a user-friendly interface and task queue management function.

Plug-and-play modular design makes it easy to disassemble and maintain.

Automated slicing for model design and repair. All-in-one collaborative additive manufacturing platform for online monitoring and print process optimization.

Explore More

Seamless Integration with MES to Help Companies Enter Industry 4.0

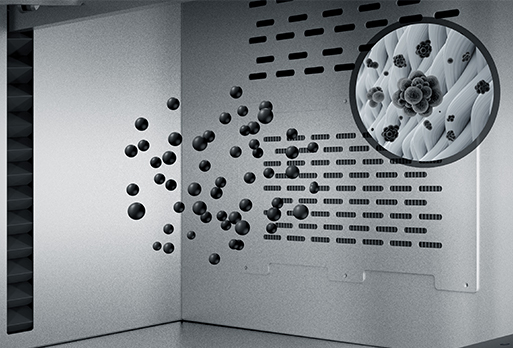

High-Standard Safety Design to Ensure the Health and Safety of Users

The HEPA filter can capture small particles generated during the printing process, and the activated carbon can absorb volatile chemicals emitted during the process.

Avoid personal danger caused by misoperation during printing.

Excellent thermal insulation design (thickened insulation layer, front door with double glass, temperature-resistant cover on the top) while the printer's working.

|

3D Printers

|

FUNMAT PRO 310 NEO |

FUNMAT PRO 610HT |

FUNMAT PRO 410 |

FUNMAT HT |

FUNMAT PRO 310 |

|---|---|---|---|---|---|

|

BUILD SIZE

|

Single Nozzle: |

610 × 508 × 508 mm |

305 x 305 x 406 mm |

260 x 260 x 260 mm |

Single Nozzle: |

|

MATERIALS

|

29

ABS+, ABS-GF, ABS-HS, ASA, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PC-PBT, PET-CF, PETG, PET-GF, PLA, PPA-CF, PPA-GF, PPS, PPS-CF, PPS-GF, PVA, SP3030, SP3050, SP5010, TPU95A, KIMYA ABS-ESD, BASF PC/ABS-FR, WANHUA PA12 |

36

PEEK, PEEK-CF, PEEK-GF, PEI 1010, PEI 9085, PEKK, PET-CF, PET-GF, PPA-CF, PPA-GF, ABS, ABS+, VICTREX AM™ 200 FIL, ASA, BASF ULTRAFUSE® PPSU, CONVESTRO PA6/66-GF20-FR, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PLA, PPS, PPSU, PVA, SP3030, SP3050, SP5000, SP5010, SP5040, SP5080, WANHUA PA12 |

30

ABS, ABS+, KIMYA ABS-ESD, VICTREX AMTM 200FIL, VICTREX AMTM450 FIL, ASA, CONVESTRO PA6/66-GF20-FR, HIPS, PA12-CF, PA6/66, PA6-CF, PC, BASF ULTRAFUSE® PC/ABS FR, PC/ABS, PC-FR, PC-PBT, PEEK, PEEK-CF, PEEK-GF, PEKK, PLA, PPA-CF, PPA-GF, PPS, PVA, SP3030, SP3050, SP5000, SP5010, WANHUA PA12 |

14

PEEK, PEEK-CF, PEEK-GF, PEKK, ABS, PC, PPA-CF, PPA-GF, PPS, PA12-CF, PA6/66, PA6-CF, ASA, PLA |

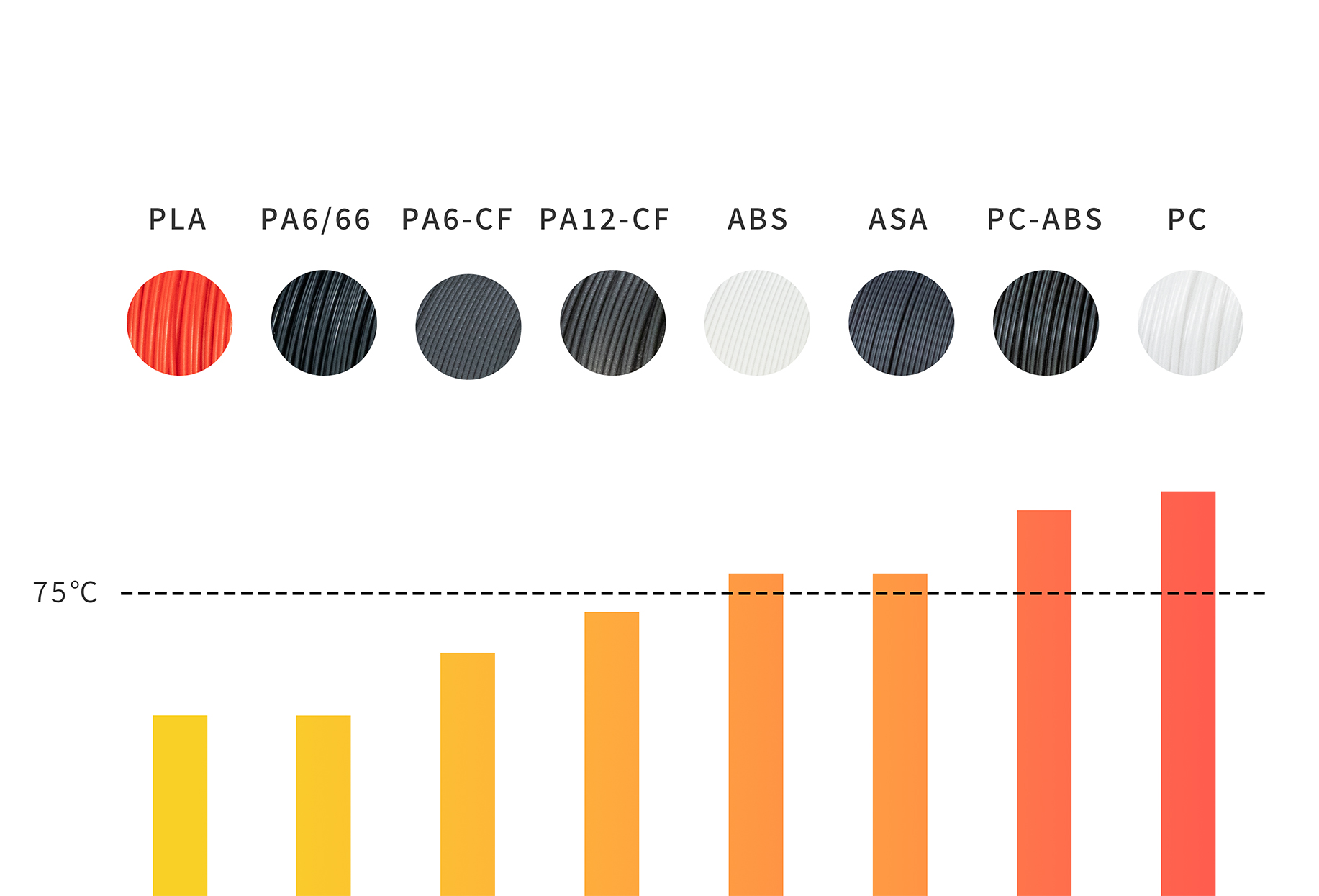

16

PA12-CF, PA6/66,PA6-CF,WANHUA PA12, PC, PC/ABS, ABS+, ABS, KIMYA ABS-ESD, ASA, BASFPC/ABS-FR, HIPS, PLA, PVA, SP3030, SP3050 |

|

PRINTER DIMENSIONS/

WEIGHT |

Overall Dimensions: 700 x 655 x 700 mm Overall Weight: 80 kg |

Overall Dimensions: 1710 x 1425 x 2080 mm With lighthouse: 1710 x 1425 x 2350 mm Overall Weight: 1450 kg |

Overall Dimensions: 728 x 684 x 1480 mm Overall Weight: 230kg |

Overall Dimensions: 543 x 501 x 645 mm Overall Weight : 63 Kg |

Overall Dimensions: 700 x 655 x 700 mm Overall Weight: 80 kg |

BROCHURE |

Download |

Download |

Download |

Download |

Download |

ALL FILAMENTS

PA12-CF is a carbon fiber reinforced PA12 (nylon 12) consumable. Compared to PA6, it is less sensitive to moisture. The carbon fiber reinforcement significantly enhances stiffness, strength, and heat resistance, while providing excellent interlayer bonding.

Explore More

PC-ABS combines the strength of PC with the toughness of ABS, making it easier to print. It offers a low-gloss finish that hides layer lines and allows for printing functional prototypes and production parts with fine details and excellent surface quality.

Explore More

PC (polycarbonate) is a strong and transparent thermoplastic with characteristics of impact resistance, high rigidity, heat resistance, and flame retardance. INTAM™ PC's unique anti-warping feature makes it easier to print with dimensional stability, ideal for demanding production and prototype printing.

Explore More

Or contact us via email: info@intamsys.com