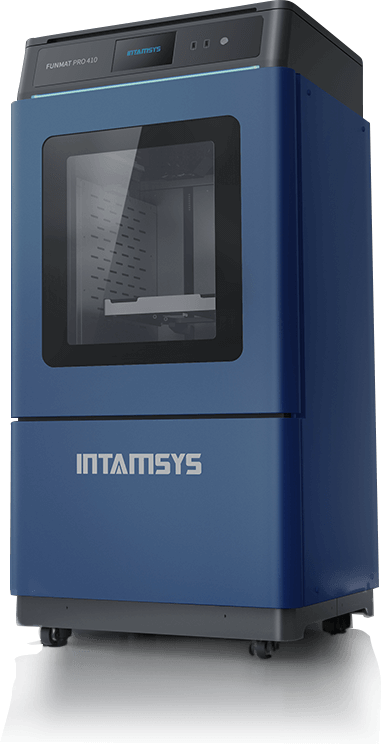

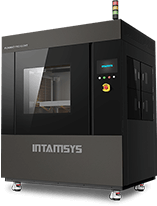

FUNMAT PRO 410

INDUSTRIAL-GRADE DUAL-EXTRUDER PEEK 3D PRINTER

WATCH VIDEO

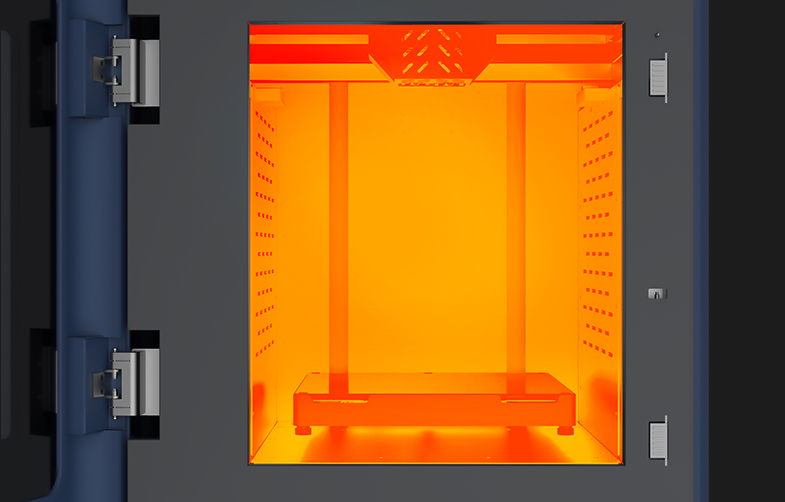

The high melting point of PEEK and its demanding requirements for high-temperature processing make 3D printing challenging.

Advanced thermal design is essential to ensure high quality and dimensional accuracy of printed components.

Equipped with high-temperature, high-power dual-nozzle printing heads capable of reaching up to 500°C, a maximum printing chamber temperature of 90°C, and a maximum printing bed temperature of 160°C, the uniformly heated chamber ensures better mechanical properties.

Provide a 6mm PEEK-specific microcrystalline glass plate to achieve high-quality production of PEEK materials. The maximum printing size is up to 305 x 305 x 406 mm.

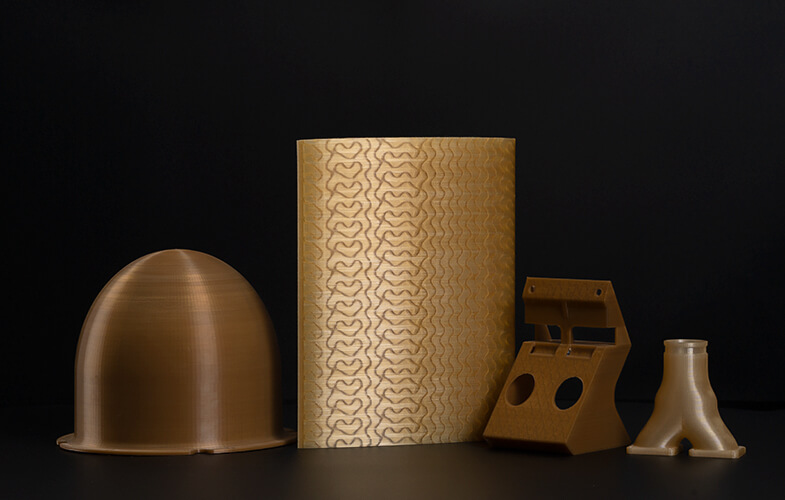

Industrial-Grade Performance, Multiple Material Printing, and Low Cost

High Performance: PEEK, PEEK-CF, PEEK-GF, PEKK, PAEK (AM200), PPS

Fiber Composite: Carbon Fiber-filled, Glass Fiber-filled

Engineering: PC, ABS, PC-ABS, ASA

INTAMSYS' 3D printers are NOT locked to INTAM™ Filaments or any other brand. The printers can accept a multitude of filaments as no two customer requests are alike. This offers versatility and cost-effectiveness.

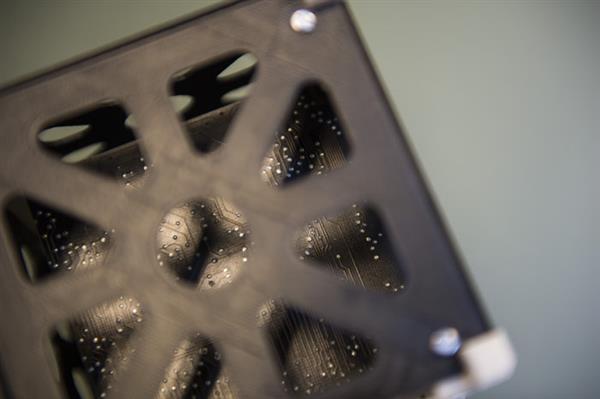

Two printheads can assist in printing support structures, ensuring high printing quality for complex geometries in conjunction with the support material solution.

When printing complex geometries such as piping, where manually removing support material is challenging, water-soluble materials can be used. These materials support the structure during printing and dissolve in water afterward, ensuring perfect printing quality.

The independent dual extruder design makes it easy to remove support material without worrying about rough contact surfaces caused by peeling.

Overall Sealed Design

Built-in Reusable Molecular Sieve to Keep Dry

Humidity Real-time Monitoring

Auto Filament Feeding

Provides automatic leveling function, simplifying the operation process, reducing user manual intervention, ensuring print bed flatness, and improving print quality and success rate.

Detects nozzle clogging and other printing problems promptly, issuing an alarm to prevent malfunctions during the printing process and reduce scrap rates.

Avoid printing failures caused by filament running out, improving printing success rates.

Effectively cleans clogged and cured print material to ensure print quality and prolong the life of the printhead.

Automated slicing for model design and repair. All-in-one collaborative additive manufacturing platform for online monitoring and print process optimization.

Explore More

|

3D Printers

|

FUNMAT PRO 310 NEO |

FUNMAT PRO 610HT |

FUNMAT PRO 410 |

FUNMAT HT |

FUNMAT PRO 310 |

|---|---|---|---|---|---|

|

BUILD SIZE

|

Single Nozzle: |

610 × 508 × 508 mm |

305 x 305 x 406 mm |

260 x 260 x 260 mm |

Single Nozzle: |

|

MATERIALS

|

29

ABS+, ABS-GF, ABS-HS, ASA, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PC-PBT, PET-CF, PETG, PET-GF, PLA, PPA-CF, PPA-GF, PPS, PPS-CF, PPS-GF, PVA, SP3030, SP3050, SP5010, TPU95A, KIMYA ABS-ESD, BASF PC/ABS-FR, WANHUA PA12 |

36

PEEK, PEEK-CF, PEEK-GF, PEI 1010, PEI 9085, PEKK, PET-CF, PET-GF, PPA-CF, PPA-GF, ABS, ABS+, VICTREX AM™ 200 FIL, ASA, BASF ULTRAFUSE® PPSU, CONVESTRO PA6/66-GF20-FR, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PLA, PPS, PPSU, PVA, SP3030, SP3050, SP5000, SP5010, SP5040, SP5080, WANHUA PA12 |

30

ABS, ABS+, KIMYA ABS-ESD, VICTREX AMTM 200FIL, VICTREX AMTM450 FIL, ASA, CONVESTRO PA6/66-GF20-FR, HIPS, PA12-CF, PA6/66, PA6-CF, PC, BASF ULTRAFUSE® PC/ABS FR, PC/ABS, PC-FR, PC-PBT, PEEK, PEEK-CF, PEEK-GF, PEKK, PLA, PPA-CF, PPA-GF, PPS, PVA, SP3030, SP3050, SP5000, SP5010, WANHUA PA12 |

14

PEEK, PEEK-CF, PEEK-GF, PEKK, ABS, PC, PPA-CF, PPA-GF, PPS, PA12-CF, PA6/66, PA6-CF, ASA, PLA |

16

PA12-CF, PA6/66,PA6-CF,WANHUA PA12, PC, PC/ABS, ABS+, ABS, KIMYA ABS-ESD, ASA, BASFPC/ABS-FR, HIPS, PLA, PVA, SP3030, SP3050 |

|

PRINTER DIMENSIONS/

WEIGHT |

Overall Dimensions: 700 x 655 x 700 mm Overall Weight: 80 kg |

Overall Dimensions: 1710 x 1425 x 2080 mm With lighthouse: 1710 x 1425 x 2350 mm Overall Weight: 1450 kg |

Overall Dimensions: 728 x 684 x 1480 mm Overall Weight: 230kg |

Overall Dimensions: 543 x 501 x 645 mm Overall Weight : 63 Kg |

Overall Dimensions: 700 x 655 x 700 mm Overall Weight: 80 kg |

BROCHURE |

Download |

Download |

Download |

Download |

Download |

ALL FILAMENTS

ABS (acrylonitrile butadiene styrene copolymer) is a common general purpose thermoplastic 3D printing consumable with good mechanical strength balance, high dimensional stability and certain chemical resistance. ABS has characteristics that make it suitable for engineering design, prototyping, functional testing, part assembly, etc.

Explore More

Polyether ether ketone is one of the best-performing plastics ever made. PEEK has excellent mechanical, thermal, and chemical resistance, making it the material of choice in some of the most demanding applications.

Explore More

INTAM™ PPA-CF is made of Polyphthalamide (PPA) with 15% chopped fiber reinforcement. Polyphthalamide (PPA) is a semi-crystalline, aromatic polyamide. Compared to nylon 6, it is stronger, stiffer, less sensitive to moisture, and has higher thermal capabilities. It also offers significant chemical, fatigue, and creep resistance.

Explore More

PC (polycarbonate) is a strong and transparent thermoplastic with characteristics of impact resistance, high rigidity, heat resistance, and flame retardance. INTAM™ PC's unique anti-warping feature makes it easier to print with dimensional stability, ideal for demanding production and prototype printing.

Explore More

The Royal Dutch Navy Conducts 3D Printing Of Frigate Parts, Reducing Reliance On Logistics And Inventory

Avoid Personal Danger Caused By Misoperation During Printing.

Revolutionize aerospace with INTAMSYS 3D printers, using PEEK to produce CubeSats for cost-effective and efficient space exploration. Explore innovative 3D printing solutions now.

Or contact us via email: info@intamsys.com