FUNMAT PRO 310 APOLLO

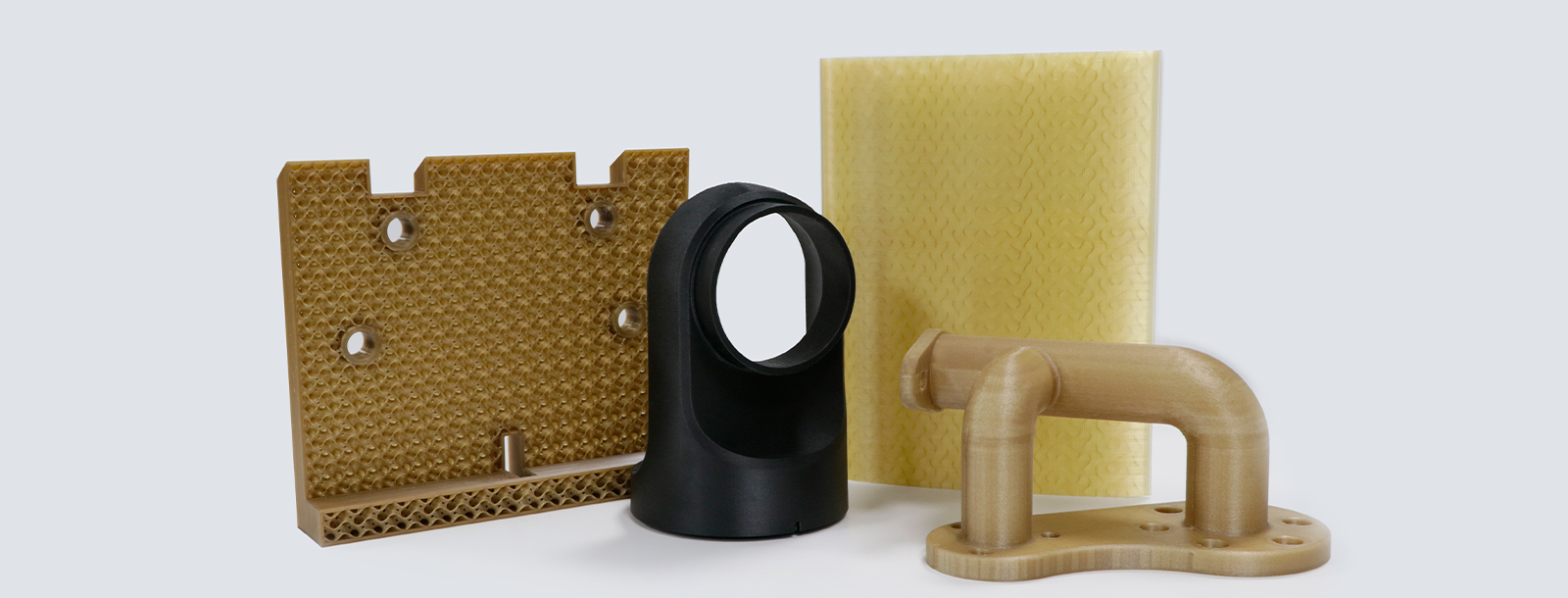

ENGINEERED FOR PAEK 3D PRINTING AT PRODUCTION SCALE

Watch Video

Delivering batch and continuous production with high-performance materials like PAEK.

Supports full-range PAEK (PEEK, PEKK, PEEK-CF, PEEK-GF)

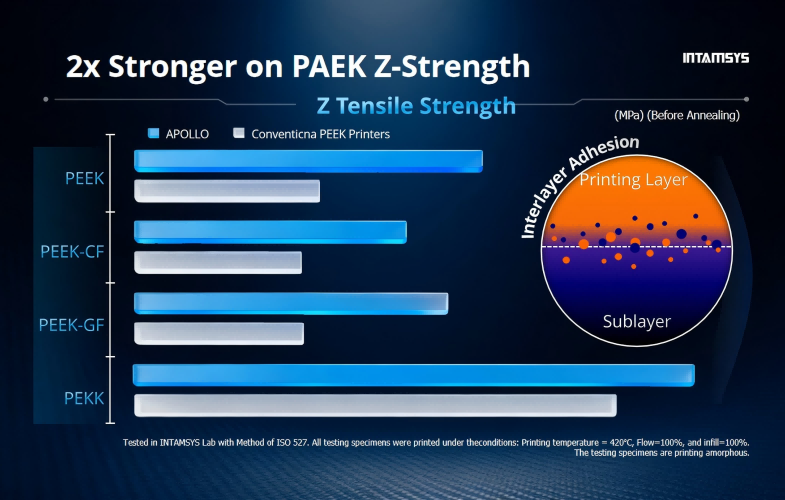

2x Stronger - Up to 40MPa Z-tensile strength

Meets the mechanical and thermal demands of high-requirement industries

Ensures reliability and durability for functional applications

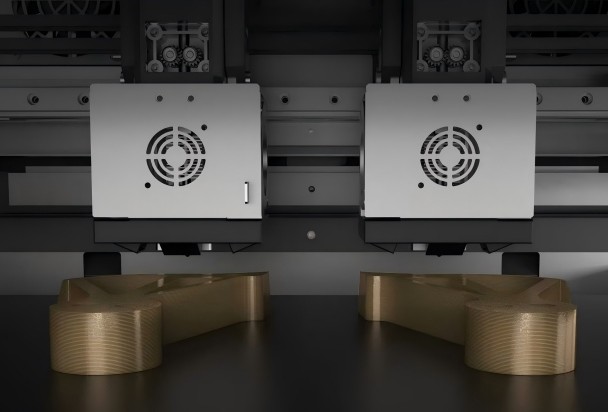

Print at up to 200 mm/s with the first PAEK-optimized dual-nozzle system in the industry, achieving more than 4 times the speed of standard PEEK printers

Independent dual-extrusion system optimized for high-temperature materials

Enables mirror mode and duplicate mode printing with double productivity

Significantly shortens production cycles while fulfilling the dual demands of batch manufacturing and end-use delivery

No prime tower is needed, reducing part print time and effectively conserves materials

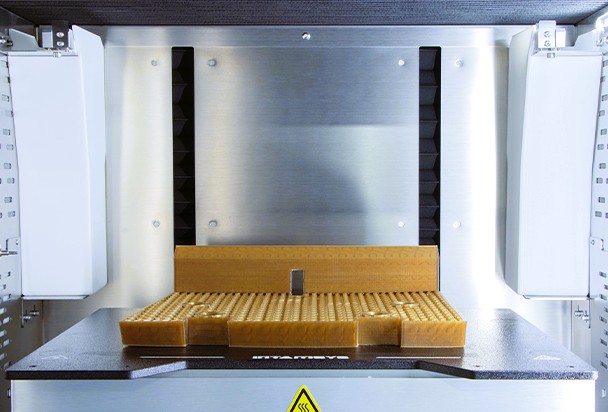

Dual 3kg active dry boxes, up to 65℃

Ensure up to one week of uninterrupted printing with no material changeovers and no downtime

Real-time data logging with INTAMQuality™ system

Full part tracking and material traceability

RFID-based INTAMSYS spool recognition

Quality validation from start to finish

Optimized hardware and software for PAEK materials

Ensures repeatability, precision, and high print success rate

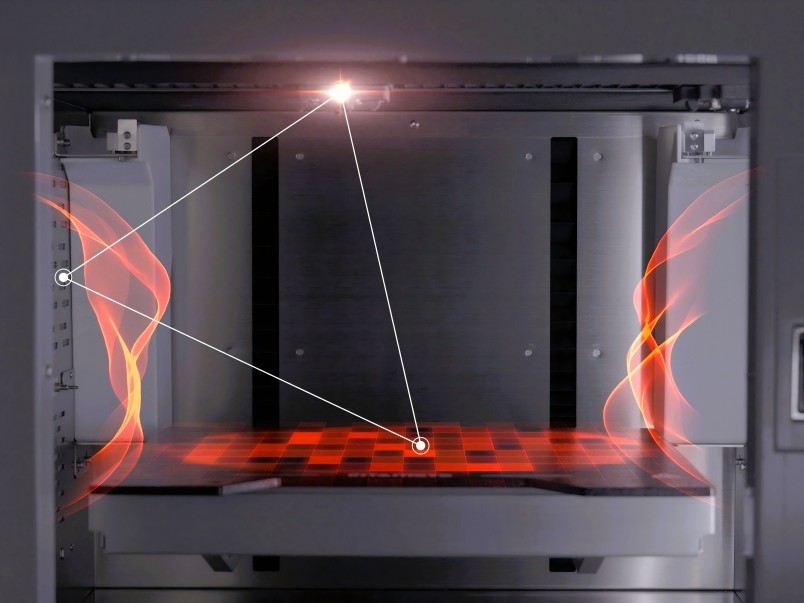

Stable chamber temperature up to 100 °C

Minimizes warping and material inconsistency

Smart, Stable, and Trackable

Achieves precise balance across thermal, flow, and path planning through coupled field control.

INTAMSUITE NEO delivers optimized toolpaths and adaptive process control for every material and geometry.

INTAMSUITE Local Print enables centralized management, remote monitoring and full remote control, from a single printer to an entire print bureau.

|

3D Printers

|

FUNMAT PRO 310 NEO |

FUNMAT PRO 310 APOLLO |

FUNMAT HT |

FUNMAT PRO 410 |

FUNMAT PRO 610HT |

FUNMAT PRO 310 |

|---|---|---|---|---|---|---|

|

BUILD SIZE

|

Single Nozzle: |

Single Nozzle:305x260x260 mm;Dual Nozzles:260x260x260 mm |

260 x 260 x 260 mm |

305 x 305 x 406 mm |

610 × 508 × 508 mm |

Single Nozzle: |

|

MATERIALS

|

29

ABS+, ABS-GF, ABS-HS, ASA, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PC-PBT, PET-CF, PETG, PET-GF, PLA, PPA-CF, PPA-GF, PPS, PPS-CF, PPS-GF, PVA, SP3030, SP3050, SP5010, TPU95A, KIMYA ABS-ESD, BASF PC/ABS-FR, WANHUA PA12 |

35

PEEK, PEEK-CF, PEEK-GF,PEKK, SP5000, AM200, ABS+, ABS-GF, ABS-HS, ASA, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PC-PBT, PET-CF, PETG, PET-GF, PLA, PPA-CF, PPA-GF, PPS, PPS-CF, PPS-GF, PVA, SP3030, SP3050, SP5010, TPU95A, KIMYA ABS-ESD, BASF PC/ABS-FR, WANHUA PA12 |

14

PEEK, PEEK-CF, PEEK-GF, PEKK, ABS, PC, PPA-CF, PPA-GF, PPS, PA12-CF, PA6/66, PA6-CF, ASA, PLA |

30

ABS, ABS+, KIMYA ABS-ESD, VICTREX AMTM 200FIL, VICTREX AMTM450 FIL, ASA, CONVESTRO PA6/66-GF20-FR, HIPS, PA12-CF, PA6/66, PA6-CF, PC, BASF ULTRAFUSE® PC/ABS FR, PC/ABS, PC-FR, PC-PBT, PEEK, PEEK-CF, PEEK-GF, PEKK, PLA, PPA-CF, PPA-GF, PPS, PVA, SP3030, SP3050, SP5000, SP5010, WANHUA PA12 |

36

PEEK, PEEK-CF, PEEK-GF, PEI 1010, PEI 9085, PEKK, PET-CF, PET-GF, PPA-CF, PPA-GF, ABS, ABS+, VICTREX AM™ 200 FIL, ASA, BASF ULTRAFUSE® PPSU, CONVESTRO PA6/66-GF20-FR, HIPS, PA12-CF, PA6/66, PA6-CF, PC, PC/ABS, PC-FR, PLA, PPS, PPSU, PVA, SP3030, SP3050, SP5000, SP5010, SP5040, SP5080, WANHUA PA12 |

16

PA12-CF, PA6/66,PA6-CF,WANHUA PA12, PC, PC/ABS, ABS+, ABS, KIMYA ABS-ESD, ASA, BASFPC/ABS-FR, HIPS, PLA, PVA, SP3030, SP3050 |

|

PRINTER DIMENSIONS/

WEIGHT |

Overall Dimensions: 700 x 655 x 700 mm Overall Weight: 80 kg |

Overall Dimensions: 700 x 655 x 750 mm Overall Weight : 80 kg |

Overall Dimensions: 543 x 501 x 645 mm Overall Weight : 63 Kg |

Overall Dimensions: 728 x 684 x 1480 mm Overall Weight: 230kg |

Overall Dimensions: 1710 x 1425 x 2080 mm With lighthouse: 1710 x 1425 x 2350 mm Overall Weight: 1450 kg |

Overall Dimensions: 700 x 655 x 700 mm Overall Weight: 80 kg |

BROCHURE |

DownLoad |

DownLoad |

DownLoad |

DownLoad |

DownLoad |

DownLoad |

ALL FILAMENTS

Polyether ether ketone is one of the best-performing plastics ever made. PEEK has excellent mechanical, thermal, and chemical resistance, making it the material of choice in some of the most demanding applications.

Explore More

INTAM™ PEKK is made from Arkema Kepstan® ingredients. As the leading material in the PAEK family, it enhances the molecular chain of PEEK, reduces crystallization speed and melting point, and improves fluidity, making it more suitable for 3D printing.

Explore More

The use of 10% high-modulus short-cut carbon fiber greatly improves the stiffness and heat resistance of PEEK. It is used in some of the most demanding applications in industries such as automotive, aerospace, defense, semiconductors, and oil/gas.

Explore More

Or contact us via email: info@intamsys.com