3D Printing in Aerospace

Rapid Design Iteration I Spare Parts I Swift Production

Advantages of using 3D printing

3D printing technology

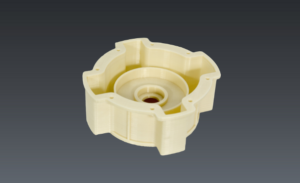

3D printing has proven to be a very effective and efficient manufacturing technique in the aerospace industry. 3D printers can help optimize the structure of complex parts. On the premise of ensuring performance, complex structures can be transformed and redesigned into simple structures, thereby reducing weight. Moreover, by optimizing the structure of the parts, the stress of the parts can be distributed in the most reasonable way, reducing the risk of fatigue cracks, thereby increasing the service life.

- Can effectively reduce the weight of the product

- With low demand and high degree of customization, 3D printing can effectively reduce costs.

- Assembly verification by printing models to speed up R&D and production.

- To improve material utilization, additive manufacturing can effectively reduce material waste.

- Optimized design can effectively improve lifespan, reliability and stability, etc., and improve overall performance.

- Increase design freedom and realize more possibilities.

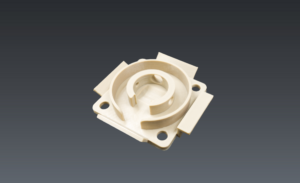

Rapid Design Iteration

Leveraging on 3D Printing technology, engineers can quickly create functional prototypes of various designs.

These prototypes can then be tested for various structural, functional, and material properties. Based on the results, modifications to the designs can be made.

3D printing has significantly reduced the time to create prototypes of automotive parts, enabling a rapid iterative design process.

Availability of Spare Parts

Stocking the right amount of spares has become a major cost component for manufacturers. And, the life cycle of automotive parts is shortened as a result of a shorter time-to-market strategy.

With 3D printing, automotive parts manufacturers can maintain a digital repository of all spare parts and print them as and when required.

Manufacturers can now offer products support for a longer period of time thus increase the product life cycle.

Production Lead Time

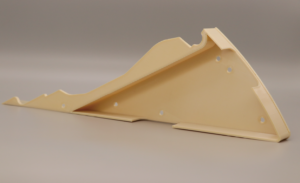

Increasing use of 3D printing solutions in automotive parts is taking place to expedite production lead time for complex parts and parts that are required in niche quantities.

Time and cost savings from tooling is another significant advantage for manufacturers and some of them have started to 3D print parts such as chassis directly.

Applied Materials

The different materials of FDM have unique properties including transparency, biocompatibility, FST certification, chemical resistance, heat resistance and strength, etc., which make the task of material selection quite simple.

Applications

Different thermoplastic 3D printing materials have unique properties, including transparency, biocompatibility, FST certification, chemical resistance, heat resistance, and strength.

These properties make the task of material selection quite simple.

- ABS

- PA6/12-CF

- PC

- PEEK

Polymer material industrial grade 3D printer

The FUNMAT series of 3D printers use Fused Filament Fabrication (FFF) technology. FFF is one of the most widely used 3D printing processes, using industrial-grade thermoplastic materials to make durable and dimensionally stable parts.

The FUNMAT 3D printer series support open material selection and can support more than 20 kinds of 3D printing materials. It is an intelligent multi-material integrated 3D printing solution.

3D Printing Solutions