Material Partnership

INTAMSYS Certified Materials╽Professional Partnerships

INTAMSYS Material Partnership is elaborated to better meet the needs of the market and demands of our customers.

INTAMSYS cooperates with mainstream material manufacturers to expand the capacity of its Open-Material 3D printers. Through continuous testing and comparison, the characteristics of the materials are used to the best applications.ᅠ

By qualifying materials, it enables us to create a detailed set of instructions to optimize the printer’s parameters for each material type. This includes chamber & extruders temperature, extrusion pressure and speed, and many more automatic adjustments making the printing process simple and repeatable.

Customers can realize the expected 3D printing effect by setting the 3D printer parameters in advance.ᅠThis can, not only optimize the settings of 3D printing materials for a large number of manufacturers, but also enable customers to obtain high-precision 3D printing quality.

Approved Material Partners

Electrostatic discharge (ESD) materials are plastics that reduce static electricity, preventing equipment damage and flammable liquids or gases from igniting. Kimya ABS-ESD is an engineered material with a surface resistivity of between 107-109 ohms per square meter. Due to special ESD additives, different filling rates and filling methods will not affect the surface resistivity.

Advantages

Applications

Semiconductor fixture, shell cover, functional test parts, etc

Support Material

HIPS (Break away)

Download the printing settings according to the certified printer

Ultrafuse® PC/ABS FR Black is a V-0 flame retardant blend of Polycarbonate and ABS – two of the most used thermoplastics for engineering & electrical applications. The combination of these two materials results in a premium material with a mix of the excellent mechanical properties of PC and the comparably low printing temperature of ABS.

Advantages

Applications

Railway, transportation

Support Material

HIPS (Break away)

Download the printing settings according to the certified printer

Outstanding thermal stability, good chemical resistance and high strength are the key features of Ultrafuse® PPSU. Parts produced by fused filament fabrication show often mechanical limitations in z-direction – the good layer adhesion of Ultrafuse® PPSU leads to balanced flexural strength properties between z- and x-direction.

Advantages

Applications

Railway, transportation

Support Material

SP5080 (Break away)

Download the printing settings according to the certified printer

The VICTREX AM™200 wire was specifically developed by VICTREX for use in the additive manufacturing field. By redesigning polymers at the molecular level, better printing results can be achieved without the use of additives or plasticizers. This new PAEK is designed to improve the quality of PAEK’s 3D printing.

Advantages

Applications

Aviation, automobile, medical, oil and gas, etc

Support Material

SP5000 (Dissolve and Break away)

Download the printing settings according to the certified printer

VICTREX AM™450 is made directly with the famous VICTREX 450g PEEK. VICTREX 450g PEEK is a standard flow polymer which provides exceptional performance over a wide range of temperatures and extreme conditions. Another highlight of this material is that it meets NORSOK M710 which can be used in oil and gas industry.

Note: VICTREX AM™ 450 filament is made from the same Victrex 450G polymer presented in this white paper. The conclusions in this paper are based on molded samples, and printed part performance will depend on the quality of the printing. Although this white paper provides some level of confidence that the polymer itself, if well printed, has resistance to these harsh environments, customers should verify that printed VICTREX AM™ 450 meets their performance expectations and confirm suitability for end-use.

Advantages

Applications

Aviation, automobile, medical, oil and gas, etc

Support Material

SP5000 (Dissolve and Break away)

Download the printing settings according to the certified printer

WANHUA PA12

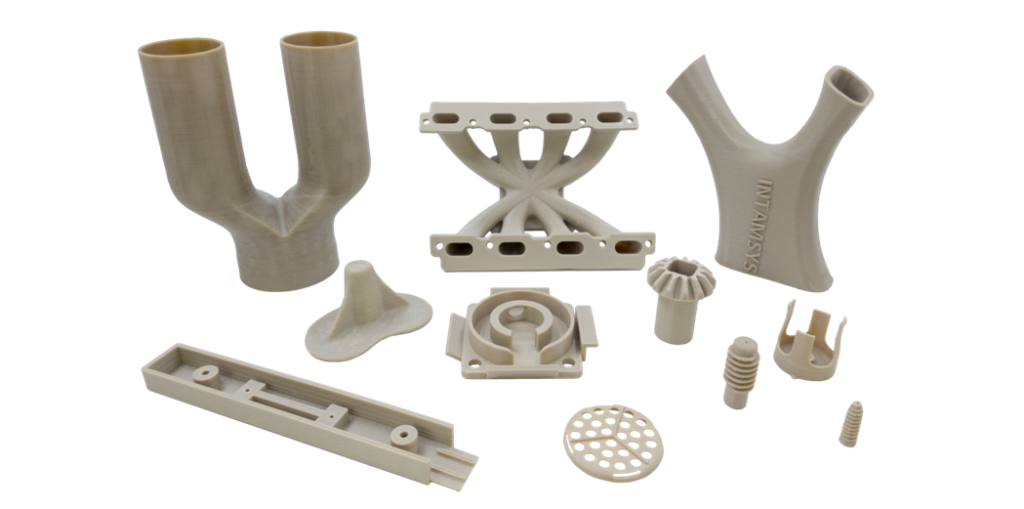

PA12 is widely used in all walks of life because of its excellent chemical resistance, low moisture absorption and wide processing window. Excellent dimensional stability, ease of printing, and excellent thermal and chemical resistance makes PA12 an excellent choice for tools, fixtures and fixtures.

Advantages

Applications

Terminal parts, fixtures, functional tests, etc

Support Material

SP3050 (break away)

Download the printing settings according to the certified printer