Applications & Industries

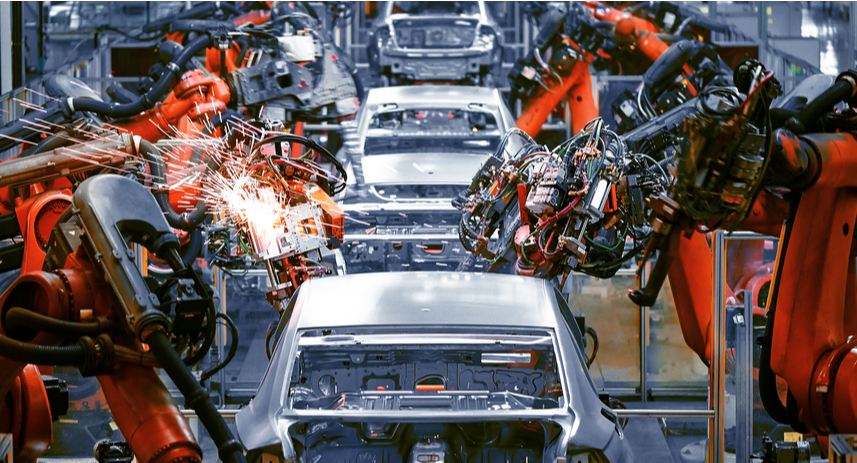

Automotive

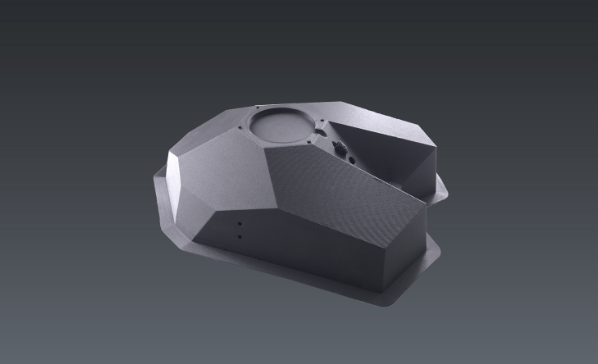

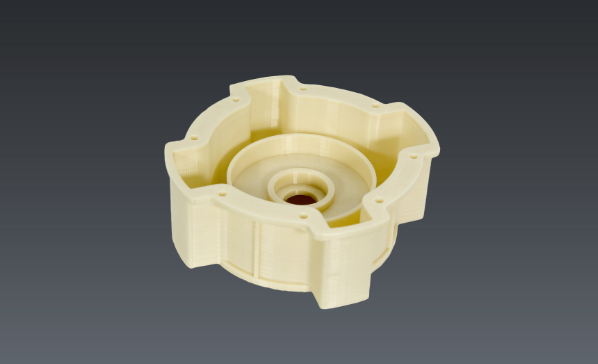

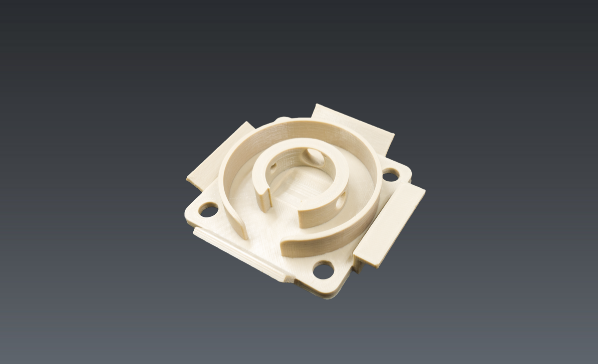

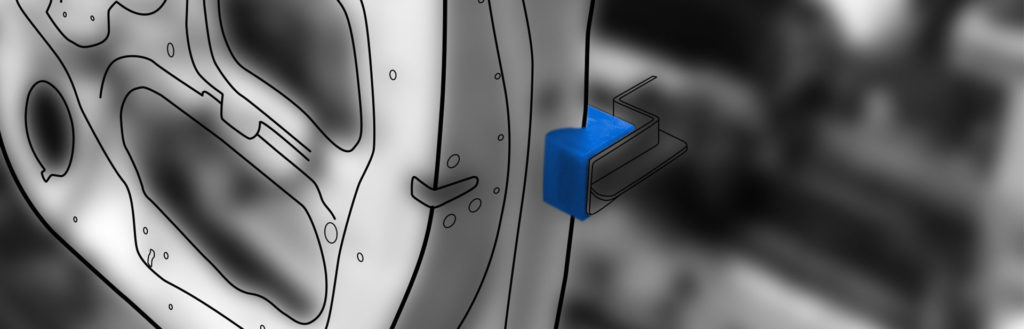

The application of 3D printing technology in the automotive industry has become more extensive, promoting the development and adaptation of processes and technologies to meet the specific needs of this fast-growing industry and solve constraints. Industrial 3D printers have opened up new paths in all stages of automobile production, from R&D prototype verification, tooling and fixtures in the production stage and modifications and spare parts in the automotive aftermarket. The automotive industry is one of the pioneers of the usage and integration of 3D printing technology.

Advantages of 3D Printing

![]() Cost and time, shorten product development time and reduce manufacturing costs

Cost and time, shorten product development time and reduce manufacturing costs

![]() Customization, fast and flexible small-batch customized production

Customization, fast and flexible small-batch customized production

![]() Reduce supply chain risks and reduce product inventory

Reduce supply chain risks and reduce product inventory

![]() Realize part integration through topology optimization, and finally achieve weight reduction and enhancement

Realize part integration through topology optimization, and finally achieve weight reduction and enhancement

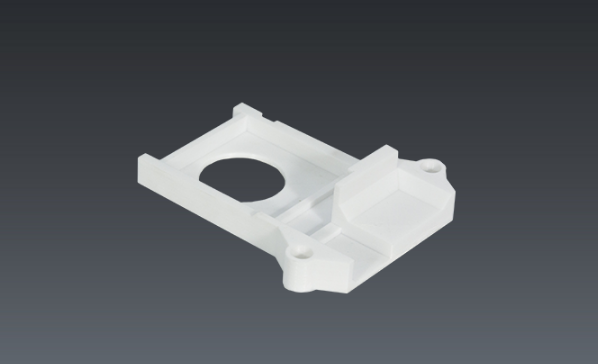

Applied Materials

Different thermoplastic 3D printing materials have unique properties, including transparency, biocompatibility, FST certification, chemical resistance, heat resistance, and strength. These properties make the task of material selection quite simple.

ABS

PA-CF

PA

PEEK

INDUSTRIAL 3D PRINTING

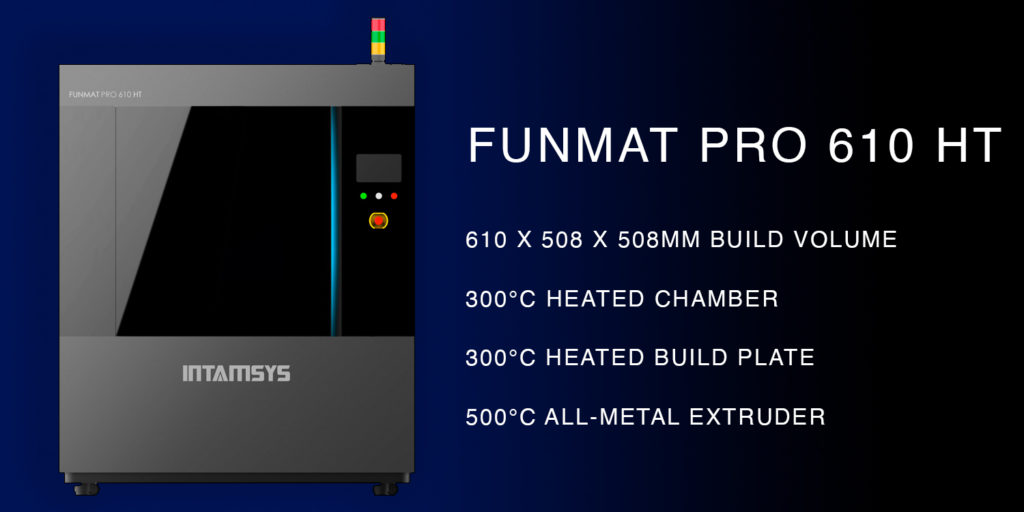

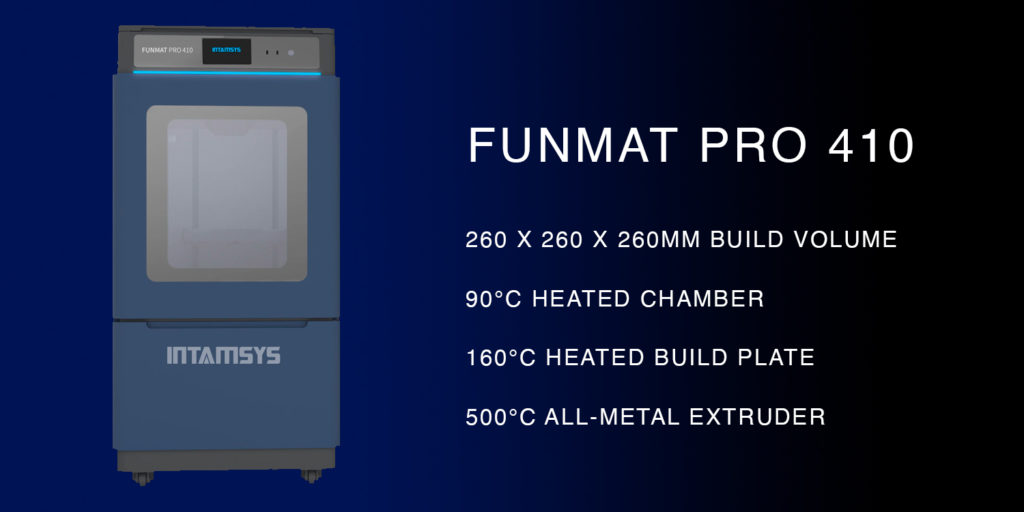

The FUNMAT series of 3D printers use Fused Filament Fabrication (FFF) technology. FFF is one of the most widely used 3D printing processes, using industrial-grade thermoplastic materials to make durable and dimensionally stable parts. The FUNMAT series of industrial-grade 3D printers support open material selection and can support more than 20 kinds of 3D printing materials. It is an intelligent multi-material integrated 3D printing solution.