A: INTAMSYS high-performance plastics include PEEK,PEEK-CF (Carbon Fiber),PEEK-GF (Glass Fiber),PEKK,PEI 9085,PEI 1010,PPSU,PPS

INTAMSYS engineering plastics include PC,PC-ABS,PC-FR (Fire Retardant),PC-PBT,PA6/66,PA12,PA6-CF (Carbon Fiber),PA12-CF (Carbon Fiber),ABS,ASA

High-performance plastics are better than engineering plastics in terms of strength, thermostability, chemical resistance weatherability, etc., . They can be used instead of metal in certain application scenarios, meanwhile, their price will be higher. The suitable materialshould be selected based on specific scenarios. If there is a need for flame retardancy, biocompatibility, or electrical insulation for instance, you can choose the material with the corresponding characteristics. Do not hesitate to contact our technicians, they can also provide you advices on that.

INTAMSYS Solutions are “open” material systems meaning ones can use 3rd party filament if desired. If you choose to use a 3rd party filament you should know that you are assuming the responsibility of material tuning. Our filament profiles may be a good starting point for your material tune but it’s very unlikely that they will produce perfect results. This is because each chemical formulation of the material is slightly different and those differences in formulation require a different material tuning. If you are using a material type that does not exist in INTAMSYS portfolio, then you will need to obtain printing parameters from the filament manufacturer to begin to create your material tune and/or you can have a look at our CAEP, Customer Application Enabling Program page.

The benefit of using INTAMSYS branded material is that we have done this tuning work for you, so your prints reaches a high quality from the first time.

The INTAMSYS Support team is not able to aid in the creation of 3rd party material tunes.

A: All 3D printers of INTAMSYS support filament with 1.75mm diameter.

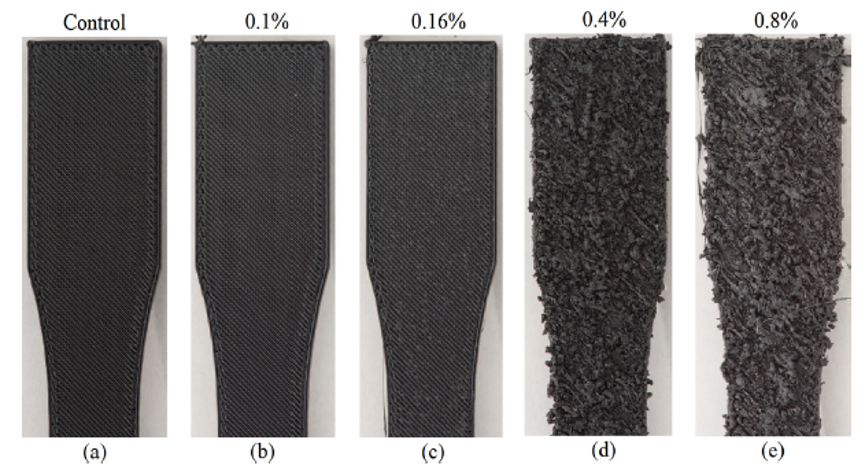

Since most FFF filaments are hygroscopic (absorb moisture from the air), it is strongly recommended to dry all your materials before use. This includes brand-new spools that were just opened. We have instructions on the drying times and temperatures printed on every spool as well as in our printing process guides. Please see the graphic below which demonstrates the impact of moisture on printing quality.

Please dry the filament according to the temperature and time conditions printed on each box and each spool of material. Alternatively, you can also refer yourself to the printing process guides which also have material drying conditions. You will need an industrial oven that can reach at least 120°C to dry the materials.

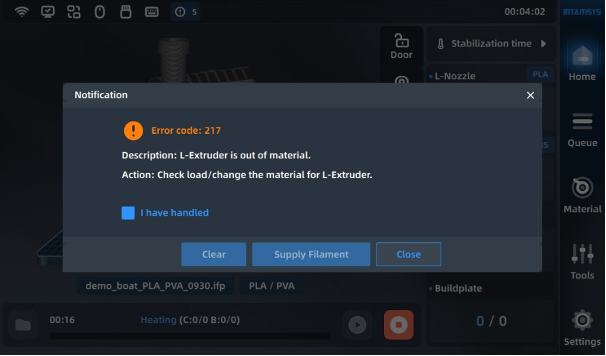

A: All INTAMSYS printers offer “filament-absence” warnings. When the filament is exhausted, the sensor will detect it and an alert message will pop up on the touch screen telling you to load a new spool of filament to resume printing. Meanwhile, the machine will maintain constant the temperature of the chamber and the temperature of the build-plate to prevent potential negative effects of temperature fluctuation when resuming the print.

A: Yes, they can.

INTAMSYS focuses on industrial 3D printing equipment manufacturing and application development. Its mature equipment (such as: the FUNMAT HT Enhanced, the FUNMAT PRO 410, the FUNMAT PRO 610HT) can print PEEK, PEEK-CF/GF, PEKK, PEI, PPSU, and other high-performance materials (FUNMAT HT & FUNMAT PRO 410 are not capable to print PEI & PPSU). We also provide quite mature processing parameter settings (embedded in the official slicing software INTAMSUITE™ & INTAMSUITE™NEO) and application cases. You can contact the INTAMSYS after-sales service team – or your local reseller for technical support information on high-performance material printing.

A: The INTAMSYS FUNMAT 3D printer series are mainly used in aerospace, national defense, automotive industry, general manufacturing, education, scientific research, medical, and more.

FUNMAT PRO 610HT: high-performance materials, large printing size, primary for industrial manufacturing, dual nozzles, high quality.

FUNMAT PRO 410: multi-materials, intelligent, industrial grade, dual nozzles, high quality.

FUNMAT PRO 310: engineering materials, desktop large printing size, dual nozzles, high quality.

FUNMAT HT Enhanced: high-performance material, desktop large printing size, high cost-effective.

Please contact us if you’d like to know more!

A: The customer has a one-year warranty after purchasing the machine. If there are any problem with the machine, you can contact your local reseller for technical support. The distributors resellers of INTAMSYS are fully trained to provide you with the best solutions and technical support. If the problem cannot be resolved by the reseller, INTAMSYS technicians will step in to help you recover your printer as soon as possible. Extended warranties are available for HT and 310 while service contracts are available for 410 and 610.

A: For the following models: FUNMAT PRO 310, FUNMAT PRO 410, and FUNMAT PRO 610HT, the files can be sent to the device through a LAN cable or a USB flash drive, taking efficiency and data security into considerations. At the same time, the remote printing function can be realized through the API via intamsuite.

The FUNMAT HT and the FUNMAT HT Enhanced use SD cards to load print files.

Q: What kind of functions and applications can dual-nozzle printers achieve?

(1) Print with support material (using the right nozzle) which make it easier to be removed from the model (printing using the left nozzle)

(2) Possibility to print dual colors but of the same material.

(3) Mirror printing features like on the FUNMAT PRO 310.

A: Setting up a reasonable temperature in the chamber and on the build-plate can make the temperature of formed model close to Tg (“glass transition temperature”), to fully release the internal stress of the model, which avoids warping, and cracking, or else surface quality issues. Printing using a heated chamber also increases the part’s strength specifically in the Z direction.

A: The bed (or also called build-plate) leveling has a great influence on the printing rate sucess. It is necessary to re-do the leveling when the following circumstances occurred but is not limited to;

- After replacing a nozzle, hot end, or other parts around the nozzle.

- After taking the extruder assembly out off the machine for repair or maintenance.

- After replacing the build-plate (glass, magnetic PI panel, PC sheet, or steel sheet),

Poor adhesion or warping issue with Raft, Brim, Skirt.

A: Yes, it’s quite easy.

(1) For firmware upgrade: connect the machine to your laptop via USB cable (in the list of machine’s accessories), then select “upgrade” option in the slicing software – INTAMSUITE™.

(2) For software upgrade (touch screen aka INTAMTOUCH™): the User Interface can be upgraded directly via the touchscreen. Just download the files, put them into a flash drive, insert it into machine’s USB port, and click the “upgrade” icon to finish the process.

(3) If you have additional questions, please find detailed instructions in your user manual.

A: For FUNMAT PRO 310, FUNMAT PRO 410, FUNMAT PRO 610HT, files can be loaded via USB flash drive. the USB flash drive can be unplugged only after the printing has started. To start the print, press the play button (triangle symbol). Removing the USB will not terminate the printing.

(Note: for the FUNMAT HT and FUNMAT PRO, unplugging the SD card will terminate the printing)

A: INTAMSYS’ 3D printers have a heat preservation feature that can be activated (or not) on demand We suggest:

(1) If you would like to make sure the print cools down slowly it is recommended to use the maintaining feature for 2-4 hours and then let the part naturally cool down in the chamber. This is a great method to reduce post-print warping due to a thermal shock. Especially for parts prone to warping which generally are large, solid, or blocky parts.

(2) If you would like to conserve power, you may disable this feature. This will start the natural cooling down in the chamber sooner. The insulation of the chamber should still prevent most post-print warping by cooling the part down slowly.

A: It is hard to conclude the precise service lifespan of the nozzles. The characteristics of the material used, the frequency of different material switch, the different using conventions, or else can affect the lifespan of the nozzle.

We recommend you observe the wear of the nozzle to determine if it needs to be replaced. Meanwhile, we recommend you prepare several nozzles, and use one individual nozzle for one specific material, this can significantly increase the service lifespan of a nozzle, and lower the possibility of nozzle clogging. (After a use of different material fixing in nozzle, carbonization can easily happen due to high temp, this short the diameter of nozzle and leads nozzle clogging)

INTAMSYS offers different kinds of nozzles for different filaments and applications.

For example: brass nozzle (for universal material with good cost-effective), CuCrZr nozzle (better temperature control, for materials with a narrow window on temperature), hardened steel (better wear-resistance performance, for materials with carbon fiber reinforcement), ruby nozzle (extreme wear-resistance performance)

A: We’ve mentioned the importance of maintaining filament drying to increase the printing quality and success rate. Therefore, we also need to control the humidity inside the filament chamber to keep filament dry. So, we offer 2 solutions:

(1) For the FUNMAT PRO 310 and the FUNMAT PRO 410, we offer 2 kinds of molecular sieves, and the filament chambers are equipped with humidity sensors, which keep the ambient humidity inside the filament chamber under control. The low ambient humidity inside the filament chamber can be maintained for more than 3 weeks under closed conditions (meaning if the box or the drawer is not regularly opened). The molecular sieve desiccant also can be repeatedly dried using an industrial oven to allow recycling and multiple reuse of the sieves.

(2) For the FUNMAT PRO 610HT, the machine continuously blow- dries compressed air into the filament chamber. The filament chambers are also heated to keep a low ambient humidity.

Q: Are any additional tools and pieces of equipment required for daily maintenance?

A: We have prepared all the necessary tools for your daily maintenance in the accompanying accessories delivered with each printer, so you do not have to buy additional tools yourself.

A: You can contact your local reseller or our after-sales service team to place the orders.

A: INTAMSUITE slicing software can read mainstream native format files .stl/.obj/.x3d/.3mf/.stp/.iges. These formats can be sliced directly without previous format conversion needed, which avoids potential model resolution degradation due to the format conversion.

A: Yes. However, please note that some unique features will not be compatible. For an optimized experience, we recommend the use of INTAMSYS’ slicing software – INTAMSUITE™ to activate the appropriate craft package of parameters and settings.

A: Key features but not limited to;

(1) The craft package of parameters and settings that leads to a high successful print rate. Save you time and improve your experience.

(2) Insert a pause at a specific layer so that you can insert things like nuts or magnets into your part.

(3) One model with multiple versions of settings displayed together, this makes the differences among different version of settings visible in one window when you check layer by layer.