Meet Pat, a visionary entrepreneur who revolutionized the automotive aftermarket industry with his innovative creation, the “Cup Keeper Plus.” This ingenious product adapts to hold various beverage containers, including flasks and water bottles, making it a must-have accessory for every car owner. Pat’s success story took an exciting turn when a major U.S. retailer placed a massive order for the Cup Keeper Plus.

However, with great opportunities come great challenges. The retailer had specific labeling and packaging requirements. They demanded labels of precise size and orientation on each Cup Keeper Plus.

Pat’s distinctive design, marked by its curved and tapered structure, posed a substantial challenge in the manufacturing process. Furthermore, the task of consistently affixing labels to thousands of Cup Keepers proved to be an additional hurdle, amplified by the varying sizes that mandated the use of dedicated fixtures. Meeting these demands required the utilization of high-strength and wear-resistant engineering materials.

Pat was not one to back down from a challenge. He enlisted the help of his talented designer, who embarked on a journey of innovation. Leveraging the power of 3D printing technology from INTAMSYS, the designer created custom tools and fixtures to meet these demanding requirements.

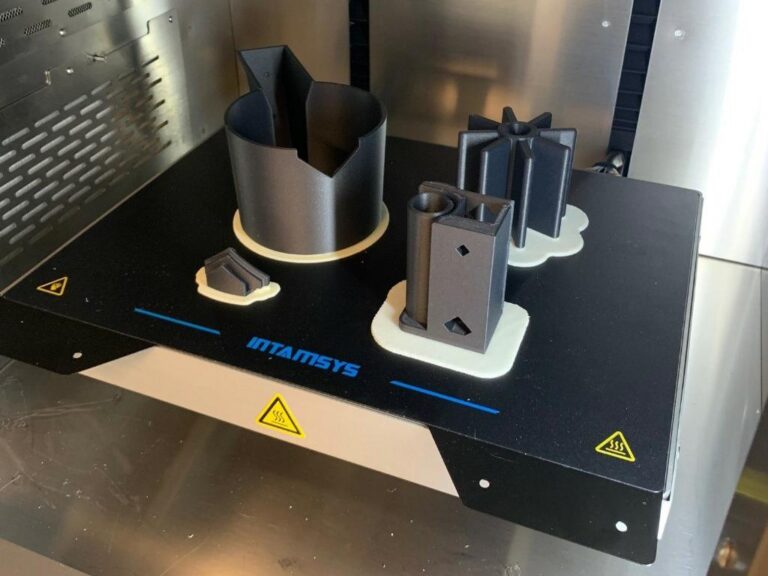

Their collaborative ideation culminated in the creation of the ‘Label Peeler,’ a groundbreaking device automating label application by expertly peeling labels from a spool. Comprising the 3D-printed Label Peeler and Label Spool Hub, this assembly integrates seamlessly into a fixture crafted from wood, as depicted below, forming a comprehensive and functional unit. Additionally, they devised the ‘Cup Fixture Assembly,’ meticulously designed to closely align with the internal geometry of the Cup Keeper Plus, ensuring stability and proper orientation for precise label application by the worker.

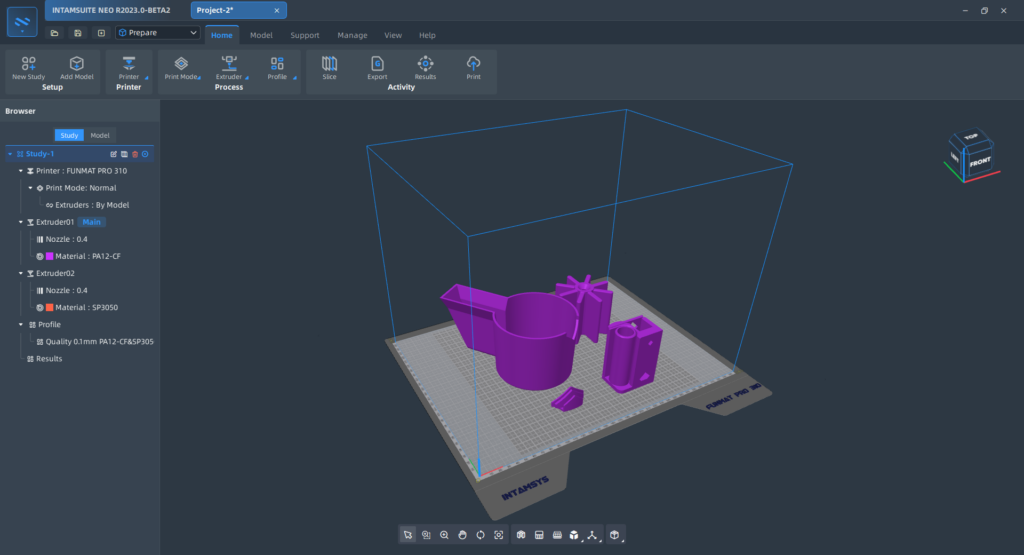

INTAMSYS became the technology partner of choice for this project, employing the advanced FUNMAT PRO 310 3D printer to transform ingenious ideas into practical tools. Pat strategically chose INTAMSYS Nylon 12-CF, a material expertly reinforced with carbon fiber. This advanced Nylon variant significantly enhances mechanical stiffness, strength, and thermal properties. Moreover, its exceptional wear resistance becomes a pivotal consideration, especially when specifying materials for precision assembly tooling of this nature.

The printer——FUNMAT PRO 310‘s compatibility with PA12-CF and its built-in drying chamber ensured optimal material performance. Its specialized support materials facilitated easy removal, guaranteeing a high-quality surface finish. With exceptional dimensional accuracy, the printer met the precise requirements for tooling and fixture manufacturing, setting a new standard for advanced 3D printing in precision applications.

With the 3D CAD files expertly converted into STL files, Pat was ready to embark on the printing journey. The INTAMSUITE software transformed digital dreams into tangible realities. The FUNMAT PRO 310 sprang into action, 3D printing each tool and fixture with incredible accuracy and speed.

The outcomes surpassed expectations, showcasing phenomenal results. The “Label Peeler” and “Cup Fixture” assemblies emerged as indispensable tools. Beyond merely printing a set of fixtures, the team faced the challenge of customizing multiple fixture sets tailored to the varied dimensions of Cup Keepers. Additionally, fixtures were tailored for different states, optimizing local usage and streamlining efficiency. With this comprehensive approach, Pat’s team established a highly efficient and reliable labeling process, seamlessly progressing from loading the Cup Keeper Plus onto the alignment fixture to applying labels with remarkable precision.

This success story eloquently showcases the harmonious blend of innovation and technology. INTAMSYS, a pioneer in the 3D printing industry, not only enabled Pat to fulfill the retailer’s packaging demands but also facilitated significant advantages in terms of design flexibility, cost efficiency, and time savings. The ability to enhance design freedom, coupled with the advantages in prototype validation, tooling fixtures, and small-batch production, played a pivotal role in securing additional orders for the Cup Keeper Plus.

For those intrigued by this story and eager to explore the possibilities of 3D printing, INTAMSYS invites you to witness the transformative power of the FUNMAT PRO 310. Dive into the world of 3D printing and revolutionize your manufacturing processes with its key features, including full-size engineering polymer printing and the ability to achieve a more delicate surface finish for complex geometries. Experience the limitless potential of 3D printing with INTAMSYS today!

![]()

INTAMSYS is a world-leading high-tech company that provides high-performance 3D printing materials, direct additive manufacturing solutions and software. Co-founded by a team of engineers with years of precision equipment development and high-performance material research, the company is headquartered in Shanghai. Currently, it has established a complete marketing and after-sales service system covering the whole world, with 2 European and American marketing and technical service centers, respectively located in Germany and in the United States. INTAMSYS focuses on aerospace, automotive, electronic manufacturing, consumer products, medical, scientific research and other industries, providing complete additive manufacturing solutions, from functional test prototyping, tooling fixture manufacturing to customized mass production. For further information, contact us at info@intamsys.com.