INTAMSYS is a world-leading high-tech company that provides high-performance 3D printing materials, direct additive manufacturing solutions and software. The company is the first 3D printing equipment supplier to offer Victrex´s new PAEK polymer, VICTREX AM™ 200, a filament designed for additive manufacturing. INTAMSYS is also the first company to be part of Victrex´s proposed filament fusion network supporting this new filament across globe. The network aims to facilitate the use of the innovative high performance VICTREX AM materials based on PAEK polymers. Specifically developed for use in additive manufacturing technology these materials are designed for high temperature resistance requirements with excellent mechanical properties for AM parts.

Shanghai, July 20th, 2020 – Victrex, a global leader in high-performance polyetheretherketone (PEEK) and polyaryletherketone (PAEK) solutions, has developed PAEK materials for additive manufacturing. The PEEK incumbent materials on the market today, although used in some AM applications, were designed for conventional manufacturing methods, such as machining and injection molding. Because of this, they have some features that aren´t optimal for additive manufacturing processes. In addition, the PEEK material used for moulding, when repurposed for filament fusion additive manufacturing, typically has a poor interlayer bonding strength, resulting in a decrease in the strength in the Z-axis direction, and the material´s excellent mechanical properties are difficult to be fully realised in printed parts.

This material was designed and optimised specifically for additive manufacturing, where up until now the typical choices were PEEK and PEKK. According to INTAMSYS´ experience on its company equipment, the VICTREX AM 200 filament has a higher Z-axis strength and has shown to date up to 80% in XY strength direction with a better fused filament forming (FFF) printing adaptability than the existing PAEK materials.

Jakob Sigurdsson, Victrex CEO, commented: “This new generation of Victrex additive manufacturing PAEK materials represents an important step forward and we are excited now to work closely with INTAMSYS. Due to excellent cooperation with companies and institutions that pursue innovation in additive manufacturing, such as INTAMSYS, as well as Victrex´s continued research, we have been making sustained progress toward creating truly innovative components based on the design freedom of additive manufacturing, combined with the high performance of PAEK.”

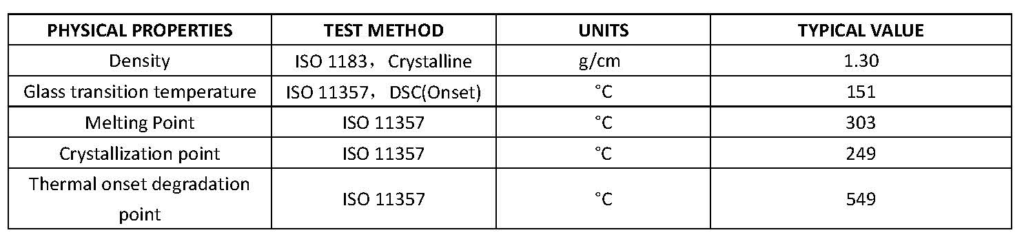

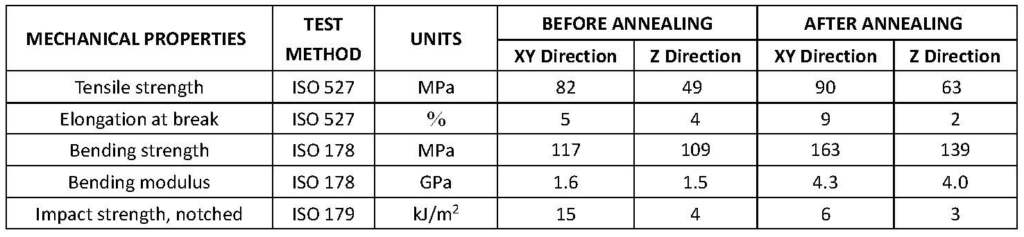

INTAMSYS has conducted mechanical performance tests on the new VICTREX PAEK filament material. The tests were performed on different printers including smart dual nozzle FUNMAT PRO 410 3D Printer. This industrial-grade, high-temperature 3D printer can print parts up to 305305406mm, can handle a variety of complex structures, and can print a variety of materials such as PEEK, PEEK-CF, PEKK, PC, PC-ABS and other high-performance materials. The physical and mechanical properties that result from the test can be seen below:

INTAMSYS´ test results to date have shown that the VICTREX AM 200 filament has a better interlayer adhesion than other PAEK materials on INTAMSYS´ machines. Compared with unfilled PEEK, it is designed with slower crystallisation, lower melt temperature, and a viscosity finetuned to the filament fusion process, such as easier flow in the build chamber after leaving the nozzle. Higher flow in open air (low shear rates) also promotes interlayer bonding and stability during printing. All of this contributes to an improved interlaminar adhesion, easier printing (less shrink and warp), and a better suitability for FDM 3D printing, compared to other similar options INTAMSYS have tested, up to this point.

Victrex new PAEK AM filament has been developed to support a variety of demanding applications because of its very high wear resistance, high temperature resistance, fatigue resistance and corrosion resistance to fluid/chemical, which when combined have the potential to increase design freedom and production cost efficiency.

INTAMSYS is a world-leading high-tech company that provides high-performance 3D printing materials, direct additive manufacturing solutions and software. Co-founded by a team of engineers with years of precision equipment development and high-performance material research, the company is headquartered in Shanghai. Currently, it has established a complete marketing and after-sales service system covering the whole world, with 2 European and American marketing and technical service centers, respectively located in Germany and in the United States. INTAMSYS focuses on aerospace, automotive, electronic manufacturing, consumer products, medical, scientific research and other industries, providing complete additive manufacturing solutions, from functional test prototyping, tooling fixture manufacturing to customized mass production. For further info please mail to info@intamsys.com

About Victrex

Victrex is an innovative world leader in high-performance PEEK and PAEK polymer solutions focusing on the strategic markets of automotive, aerospace, energy (including manufacturing and engineering), electronics and medical. Every day, millions of people use products and applications containing our materials – from smartphones, aeroplanes and cars to oil and gas operations and medical devices. With over 40 years´ experience, the company is developing world leading solutions with PEEK and PAEK-based polymers and selected semi-finished and finished parts which shape future performance for its customers and markets and drive value for its shareholders. Find out more at http://www.victrex.com and http://www.victrex.com/EN/additive-manufacturing