Interview with INTAMSYS @3DNatives

SEPTEMBER 20TH 2019

3DN: Could you introduce yourself and tell us your relationship with 3D printing technologies?

I am Charles Han, CEO of INTAMSYS, a Shanghai based industrial 3D printer manufacturer for polymers. INTAMSYS was originally created by a group of engineers with a high speed, high precision equipment development and with a clear mission: customize our future life, which means drive 3D printing from rapid prototyping for R&D to direct manufacturing for production. We gathered our experiences and knowledges and then decided to enter the 3D Printing market back in 2014. At the time we were already convinced 3D Printing would have a huge impact on future manufacturing. When we look at the 3D Printing market in 2019 and its evolution, we were absolutely right. And the best is yet to come.

3DN: How did INTAMSYS start and what were its first objectives?

In 2014, INTAMSYS or should I say Honsmaker (our company original name), entered into the 3D Printing Industry with the idea to integrate our high speed / high precision technology into a 3D printer design. We then quickly became renown for our PEEK printing capabilities thanks to the already popular FUNMAT HT. At the time our team already believed that High Performance Functional Materials like PEEK would become more and more popular and their applications more and more diverse.

Since then we have not stopped providing our customers with reliable industrial 3D Printing solutions for High Performance Functional Materials (such as PEEK, PEKK, ULTEM (PEI), etc.) and for other Engineering Materials (such as PC, PA, ABS, etc.).

3DN: Why did INTAMSYS decide to focus on HPPs?

In the AM market, a lot of the requirements can be met only by using high functional materials like PEEK, PEKK, ULTEM (PEI) and PPSU. PEEK along with other high performance polymers (HPPs) are well-known for their high temperature endurance, their acid resistance and thus can be used in the medical industry because of their biocompatible function.

For the automotive, the aerospace or for any other industries, we want to make the 3D printing technology for high end materials even more reliable.

Why do High Performance Functional Materials are challenging? Because most of the high end functional materials require high temperature environments, which means a high temperature chamber. We have to innovate to meet these tough requirements without infringing on existing IP. A long thermal analysis had to be performed and then the thermal design could be optimized accordingly.

3DN: What does INTAMSYS offer as of today?

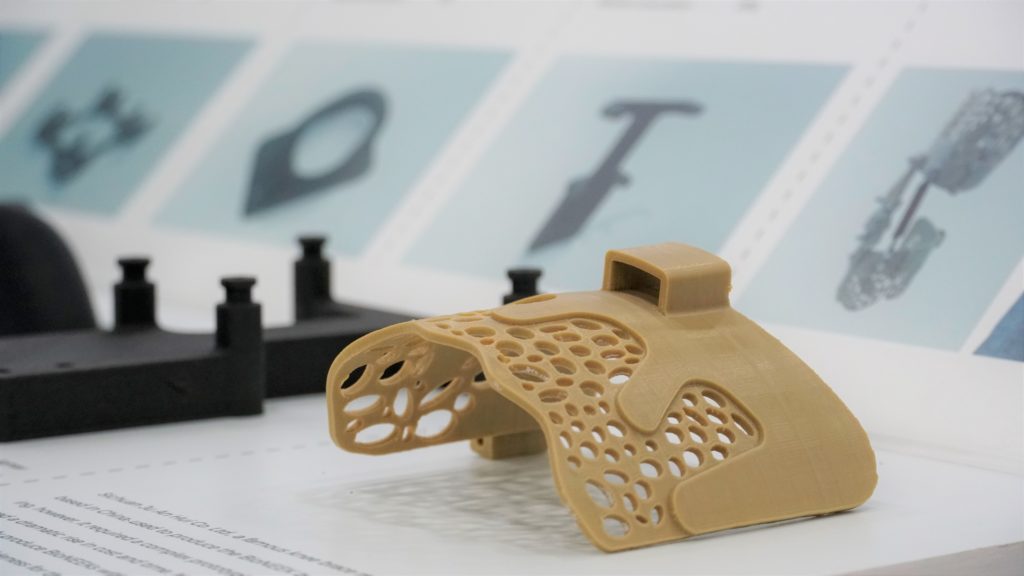

As of today, INTAMSYS offers a broad range of 3D Printing Solutions, enabling its customers to use 3D Printing not only for prototyping but also for concrete applications in different industries, such as automotive, oil & gas, medical sector, aerospace, etc.

The 2 latest addition to the FUNMAT serie, the FUNMAT PRO 410 and the FUNMAT PRO 610 HT, provide an All-in-One Solution meeting the most demanding requirements of the AM industry.

Aiming at offering a one stop solution for our customers using the FUNMAT 3D Printers, we are now cooperating with top filament manufacturers to provide dedicated printing profiles to customers. According to their application and to the material they want to use, Customers can benefit from the preconfigured settings in our software INTAMSUITE, resulting in an even better printing quality.

3DN: What are the key factors of your brand’s success?

The reliability and the capabilities of our printers are key. Finding a reliable 3D printer, which can not only print High Performance Functional Materials (PEEK, PEKK, ULTEM (PEI), PPSU, etc.) but also a wide range of Engineering Materials (such as PC, PA, PA-CF, ABS, TPU, etc.) with a great precision can be difficult.

3DN: What are your plans for the future? Where do you see INTAMSYS in 10 years?

As we just opened an office in Stuttgart – Germany, our plan is to continuously try to get closer to our customers and resellers.

Therefore, we truly believe in proximity. That is why we now attend major exhibitions with a worldwide audience so that we can share with the many our latest 3d printing innovations.

And by the way, you can come and meet us during TCT Birmingham (UK) at the end of September, & during the Formnext in Frankfurt (Germany) at mid of November.

3DN: Do you have any last words for our readers?

Continuously innovating and improving the 3D Printing cutting-edge technology is what drives and motivates us every day.

Read the interview on 3DNatives: https://www.3dnatives.com/en/intamsys-interview-170920194/

Contact: info@intamsys.com