INTAMSYS proudly announces the renewal of its sponsorship for the GreenTeam Uni Stuttgart e.V. This marks another year of collaboration between INTAMSYS and the GreenTeam. The company continues to support with its 3D Printing Solutions in the team´s pursuit of innovation and excellence in the world of electric racing cars.

E0711-13 in Season 2023 (Photo credit: GreenTeam)

Founded in 2009, GreenTeam’s goal was to adopt the emerging trend of fully electric Formula Student race cars. The team has solidified its presence by independently developing its own vehicles. Since 2017, they have been developing both electric and autonomous driving cars. Currently, the team consists of around 50 students with diverse academic backgrounds.

They participate in one of the largest student competitions, the Formula Student, with their self-developed electrical & driverless racing cars. Since 2010, the team has been continuously in the top 10 of the worlds ranking list of electric racing cars.

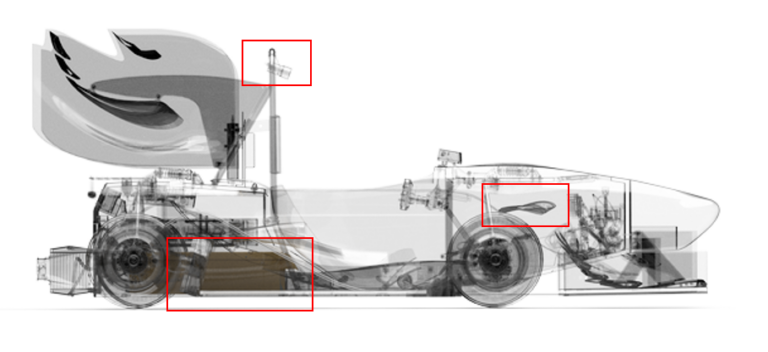

The team has been using 3D printing technology over the past few years. In 2023 season, the latest car model E0711-13, which was fully designed and developed by GreenTeam, also includes many 3D printed parts in different areas such as inside the accumulator and the braking system, wings, and power electronics. The car approximately has more than 200 components which were created using 3D printing technology.

Some Examples of 3D Printed Parts with INTAMSYS

Every year during the design process of the car, GreenTeam faces many challenges to overcome. For example, the parts inside the accumulator should be fire retardant and there should be a barrier between the parts with different voltages. These are the requirements of Formula Student Germany, the competition committee, and they should be followed. The team had to find a way to follow these rules with a minimum amount of car weight.

Additionally, many parts in the car are only needed in a small number of pieces which are redesigned over and over again to reach the perfect results. So, the need of rapid prototyping became evident for the team.

INTAMSYS sponsored GreenTeam for the first time in 2021 to find a solution for these obstacles. Following successful training sessions, the team has started using INTAMSYS FUNMAT HT, a desktop FFF 3D Printer. Since then, every year new training sessions has been held with the new team members to make sure the printer is used in the most efficient way possible.

INTAMSYS 3D Printed Part Locations inside the car (Photo credit: GreenTeam)

3D Printing with INTAMSYS enables the production of non-conductive, fire-retardant components in smaller quantities, ensuring a cost-efficient and time-effective alternative.

The FUNMAT HT is suitable for printing high-performance polymers like PEEK or ULTEM™, it can be also used to process all traditional engineering materials like PA, PC, ABS, and others. So far, ULTEM™ 1010, PolyCarbonate and ABS have been used by the team thanks to their high mechanical properties while keeping the final parts lightweighted which is crucial to achieve in motorsports.

AirGeo

Left Part – Season 2022, Right Part- Season 2023

The AirGeo has been one of the many 3D printed parts over the past few years. This part is located inside the accumulator in the backside of the car. It holds cables, relays, fuses, and many PCBs from light indicators for the accumulator to the accumulator management system.

The part was fully designed by GreenTeam. The design prioritized mounting the relays on the PCB, minimizing cables, ensuring compactness for airflow window placement, and putting barriers between high-voltage and low-voltage components (FSG rule).

For the part, the FUNMAT PRO 610HT was used thanks to its large build volume (610 x 508 x 508 mm). The material choice was ULTEM™ 1010, which offers not only high strength-to-weight ratio and but also a low FST (Flame, Smoke and Toxicity) rating.

Although the design of the AirGeo 2022 and 2023 have been kept same in many ways, the main difference appears in the front section. Since the PCB has been changed and a new part has been added in front of it, the team redesigned the AirGeo, connecting the PCB from the back side only.

The Newest Car Developed by GreenTeam at Formnext 2023

INTAMSYS had the pleasure to showcase the car, E0711-13, and to welcome the GreenTeam at its booth at Formnext 2023. The team members of GreenTeam explained the visitors and 3D Printing enthusiasts how using INTAMSYS 3D FFF Solutions has been beneficial for them.

Announcement of the Sponsorship

INTAMSYS has been truly impressed by the success of the GreenTeam over the years and very proud to be a part of their journey. The company looks forward to their achievements and successful collaboration with GreenTeam Uni Stuttgart e.V.

Introduction to partners in this case

About GreenTeam

The GreenTeam Uni Stuttgart e.V. is a student association founded in 2009 that participates in the largest student racing competition, Formula Student, with its self-developed electric & autonomous racing cars. The team has been continuously in the top 10 of the worlds ranking list of electric racing cars since 2010.

![]()

INTAMSYS is a world-leading high-tech company that provides high-performance 3D printing materials, direct additive manufacturing solutions and software. Co-founded by a team of engineers with years of precision equipment development and high-performance material research, the company is headquartered in Shanghai. Currently, it has established a complete marketing and after-sales service system covering the whole world, with 2 European and American marketing and technical service centers, respectively located in Germany and in the United States. INTAMSYS focuses on aerospace, automotive, electronic manufacturing, consumer products, medical, scientific research and other industries, providing complete additive manufacturing solutions, from functional test prototyping, tooling fixture manufacturing to customized mass production. For further information, contact us at info@intamsys.com.