4D Concepts GmbH is now a more than 25 years-old well-established 3D printing service company located on the outskirt of Frankfurt in Gross-Gerau, Germany. To pally the demand for high-performance prototypes made from modern high-performance thermoplastics, they added the INTAMSYS FUNMAT PRO 610HT to their portfolio.

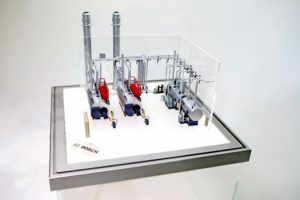

4D Concepts’ focus is on prototyping and model construction services in the 4th Dimension-Time. They combine 3D printing with conventional component processing methods. In this way, they can quickly realize the customer’s ideas and manufacture prototypes, models, or exhibits in all sizes. Even small series production is not a problem.

3D printing is an important part of their service offering. They also own and have expertise in many technologies like ColorJet Printing (CJP), Selective Laser Sintering (SLS), Stereolithography (SLA), PolyJet Printing, MultiJet Printing (MJP), Multi Jet Fusion (MJF), and Fused Filament Fabrication (FFF).

And since 1998, they are also an official reseller of 3D Systems printers which they also use for themselves.

“We accompany our customers in a professional manner throughout the entire project - from planning and design to the prototype or the production of a complete series. Combining our 3D printing processes with conventional component processing, post-processing and surface refinement of the prototypes, small series or even a trade fair exhibit is our daily business. Since the company was founded in 1995, our experienced team in Gross-Gerau has made a name for itself well beyond the borders of the Rhine-Main area. We are one of the leading service providers for everything to do with 3D printing and have more than satisfied customers from a wide variety of industries - from the automotive and consumer goods industries to mechanical engineering and companies from the medical technology sector”

Alex Di Maglie, Managing Director, said

With growing demand from aerospace, automotive, food, and medical sectors, and despite the wide variety of 3D printing technologies they owned already, they were missing a printer capable to print super polymers like PEEK, PEKK, PPSU, PPS, or ULTEM™. 4D Concepts wanted to expand its offering and materials portfolio to product developers and designers.

They had a look on the market at printers capable to print high-performance polymers (FFF) technologies. They first turned to the most known names, but they couldn’t find exactly what they were looking for.

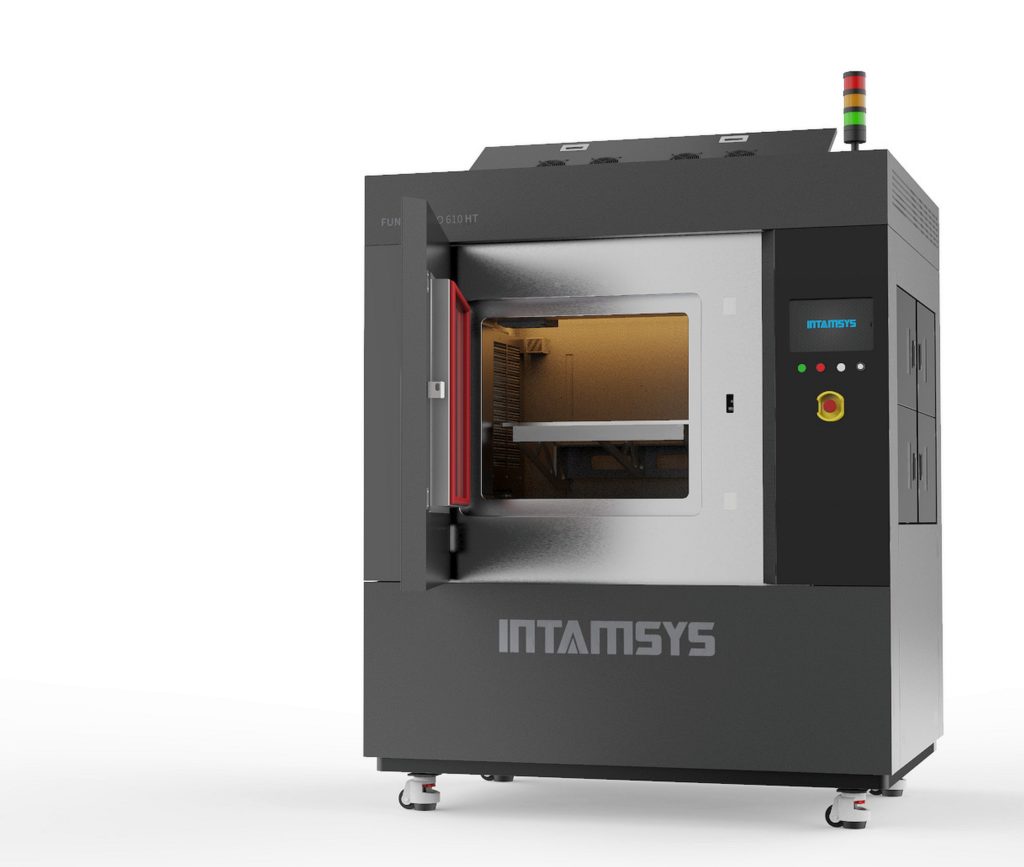

They were looking for a large build volume (to be able to print all sizes from small to big parts), an open material system (capable to go beyond for the customer’s application and leaving room to experiment and do filament research), and the right price/value.

They went for INTAMSYS and received their FUNMAT PRO 610HT in June 2021. Since the purchase of the printer, they have printed many prototypes, some end-use parts, and from time to time jigs/fixtures and tooling parts.

As the printer has a high chamber temperature (up to 300°C), it also means that all temperatures in between are covered too. 4D Concepts has printed out parts of many plastic types; from PLA, ABS, PC, to PAEK, PEEK, PEI 9085/1010.

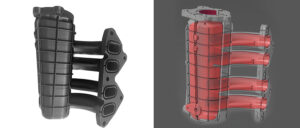

4D Concepts – prototype of a temperature-resistant pulley made of glass-fiber reinforced PEEK (PEEK-GF).

Tom Neumann, Application Engineer at 4D Concepts for FFF Technology, shared, “The most important features are to me the automatic reloading system in the filament chambers (when the spool is empty it goes automatically to the next chamber), the high-performance dual nozzles (500°C) and that the printer is an Open System. It allows us to choose the right material for our customers’ applications.”

The application of high-end filaments made of high-performance plastics such as ULTEM™ is not new to the field of 3D Printing. However, it requires both, a wide range of skills (materials and production) and the appropriate machinery.

Thanks to its large-format 3D printer from INTAMSYS, 4D Concepts can now process a wide range of high-end plastics with excellent thermal and mechanical properties for prototyping. Parts are out of ULTEM™9085.

4D Concepts GmbH

Frankfurter Strasse 74

64521 Gross-Gerau

Telefon +49 6152 92310

E-Mail mail@4dconcepts.de