One can wonder what are the benefits of 3D printed end-use parts for yachts. Well, yachts are made to their own specifications, and everything fits in afterward. Many pieces need to be specifically made or customized before installation. 3D printing can help reduce costs and manufacturing time but not only, it allows a greater choice of materials and more design freedom.

Sea3D is a company focusing on Research and Development in 3D printing capabilities. It was established by Adam Hauck, an experienced Superyacht captain, and Nick McMullen, an innovative engineer working in the yachting industry, both for many years. They have joined forces amidst the Covid pandemic to create an industrial 3D printing company in Palma de Mallorca.

The young company wanted to print high-quality parts and out of technical materials that can be used for end-use parts with real-world use.

3D printing allows the company to make any number of different parts to fit and match exactly with the various spaces onboard a yacht. The CAD model can be created according to the space allowed and fits the needed requirements. With the advancements in filaments and precise high-quality printers like the FUNMAT HT, Nick and Adam are able to have a high control on cost, produce parts faster than traditional manufacturing, and use materials that are better suited to the intended function than in conventional methods. The FUNMAT HT is an open material system that doesn’t come at an extra cost, thus allowing them to test many types of filaments.

The criteria to go for a FUNMAT HT was to be able to print the kind of high quality and technical materials that can be used for end-use parts. The duo was looking for their prints to be immediately used onboard for real-purpose use. The capabilities of the FUNMAT HT allow them to print with materials that rival or even surpass various metals and machines plastics. Sea3D researched the topic and decided to go for INTAMSYS’s industrial desktop printer as it was the best way to hit the ground running and produce functional parts for yachting. The printer was purchased with the expert advice of now newly entitled Windforce located in Barcelona.

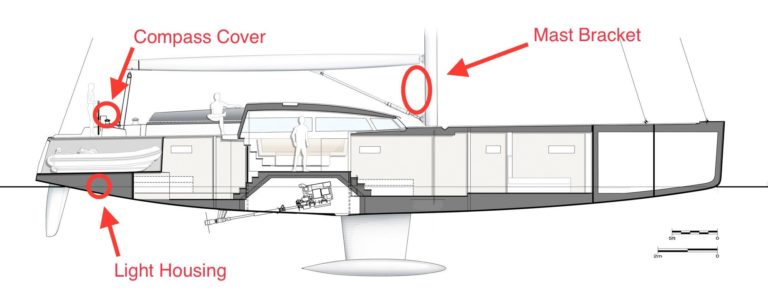

Among a vast choice of industries covered, Sea3D designed and printed several parts at a customer’s request.

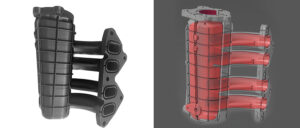

This is a new part developed by the team. The customer was looking for a bracket to hold the instrument screens away from the mast so the lines could run free behind it without blocking the visibility. The captain also wanted something strong as there may be some climbing on the brackets while managing the sails.

With the help of the captain that designed the CAD model, Sea3D was able to print it in one piece using the maximum X & Y-axis area on the FUNMAT HT.

But on which material should the piece be printed out of?

They initially printed the bracket out of PLA-CF and sent it to the captain who fitted it and made some changes according to the curvature of the mast. However, the first bracket has now been on for a full summer with heavy use and still looks brand new.

They printed then two more brackets with the needed changes. The final designs were printed out of carbon-fiber-reinforced Nylon.

Adam and Nick were impressed with the strength and durability of PLA-CF. But they remain curious as to the differences between PA-CF and PLA-CF. They are looking forward to doing continued testing with this design and possible materials.

This is a replacement for a part located on the helm. The original part was made of a type of rubber and had yellowed from the sun and was tearing off.

It was a complex design due to its hollow dome shape. Nick and Adam had to adjust for use of support on the inside and a few liner details such as the yacht name, a “lip” so it snaps in place, etc.

The part was printed out of ASA, for its UV resistance. It is also very durable and impact resistant. The captain wanted a black color to match parts of the boat and desired a hardcover instead of the original flexible one from before. This has been on board since the start of summer 2021, out in the sun, in contact of the sea, and exposed to the sea weather, and the part still looks great!

There are lights located under the helm in the Lazarette. These lights light up under the water. The part on the picture didn’t exist before. It came from the will of protecting them from damage, water, or oil. The captain wanted some housings made that could come off easily so he could still service the lights.

They went for a simple and robust design. The parts needed to be strong and out of sight. There were needs to have vents to disperse the heat and a base that the housing could attach to, so the design incorporated these features.

The material choice was PA-CF for its mechanical strength since there may be cargo falling and hitting them – or people stepping on them. In addition to its strength, carbon-fiber-reinforced Nylon has a resistance to chemicals like engine oils, fuels, or cleaning chemicals that could be found in the vicinity.

Sea3D remains excited in continuing improving their current products and continuing to experiment and improve the parts.

The company is expanding, and for more exposure, Sea3D printed again the parts to be displayed at INTAMSYS’s booth during Formnext 2021 in Germany.

ABOUT SEA3D

“We Create Solutions and Make A Difference.”

Their services include the smallest most intricate prints to the most elaborate large-scale industrial projects.

Adam Hauck, an experienced Superyacht captain, and Nick McMullen, an innovative engineer working in the yachting industry, both for many years, have joined forces amidst the covid pandemic to create an industrial 3d printing company in Palam de Mallorca called Sea3D. Their dynamic collection of printers allow them to offer large-scale industrial 3D printed solutions for a wide range of industries. https://sea3d.net/

ABOUT WINDFORCE

WindForce is an expert in large format additive manufacturing in many sectors. From design and architecture to advertising, retail to the transport sector including automotive, rail, and marine.

The company is part of DFactory – http://dfactorybcn.org, the most important 4.0 innovation center in Southern Europe. Windforce proposes to accompany its customers to make the leap to large format digital 3D printing, supporting them in every step of the way and supporting their ambitions to make 3D printing a profitable dimension of their business. www.windforce.es

ABOUT INTAMSYS

INTAMSYS 3D Printing All-in-One Solutions bear the ambition to make future lives fully customizable due to the infinity of possibilities the Additive Manufacturing Industry offers. Meeting the most demanding industrial standards, INTAMSYS 3D Printers are optimized for applications in industries as diverse as Automotive, Aerospace, Oil & Gas, Medical sector, Jigs & Fixtures, or even Education.

Contact: info@intamsys.com

3 Comments