The application of PEEK (polyetheretherketone) in 3D printing of human hard tissue substitutes has drawn extensive attention in recent years. With excellent biocompatibility and chemical stability, and density and mechanical properties close to those of human bone, PEEK is an ideal material for bone substitutes and has become a leading candidate material to replace metal implants and prostheses in orthopedic, spinal, and craniomaxillofacial surgeries. Combined with 3D printing technology, PEEK is expected to be widely used in the field of orthopedic implants. The advanced medical application project of PEEK 3D printing conducted by INTAMSYS in collaboration with Tangdu Hospital of Air Force Medical University is a pioneering practice in this field.

PEEK 3D printed implants in the treatment of skull,

thoracic ribs and nutcracker syndrome

Skull reconstruction surgery

In conventional skull implant procedures, hard and lightweight titanium mesh is commonly used to repair damage or fill voids. Meanwhile, the medical community is in constant pursuit of new medical implant materials to improve surgical outcomes and post-operative patient experience.

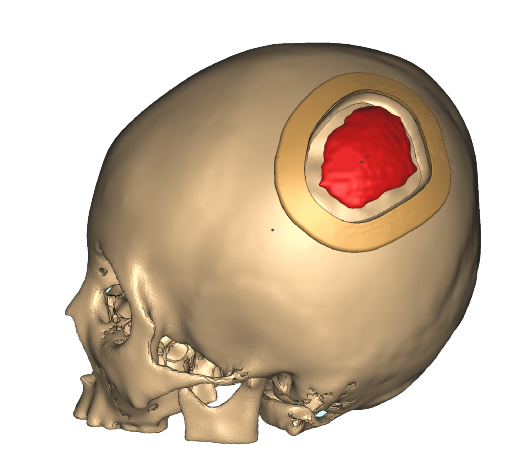

Skull

implant protocol

What kind of technique can best meet the surgical requirements?

A patient at Tangdu Hospital of Air Force Medical University had a head tumor and needed skull implant to repair the damaged area. Based on the patient’s CT scan data, the surgeons designed a “tailor-made” skull piece structure using CAD software. They printed customized skull pieces by FDM (fused deposition modeling) using high-performance PEEK material with the help of the 3D printing technology of INTAMSYS. During the surgery, the surgeons successfully repaired the damaged area of the patient’s skull by precisely implanting skull pieces according to the protocol. The postoperative examination showed that the skull pieces fitted perfectly with the patient’s natural bone without artifacts, and the patient recovered well after the operation.

Versatile application in surgical implants

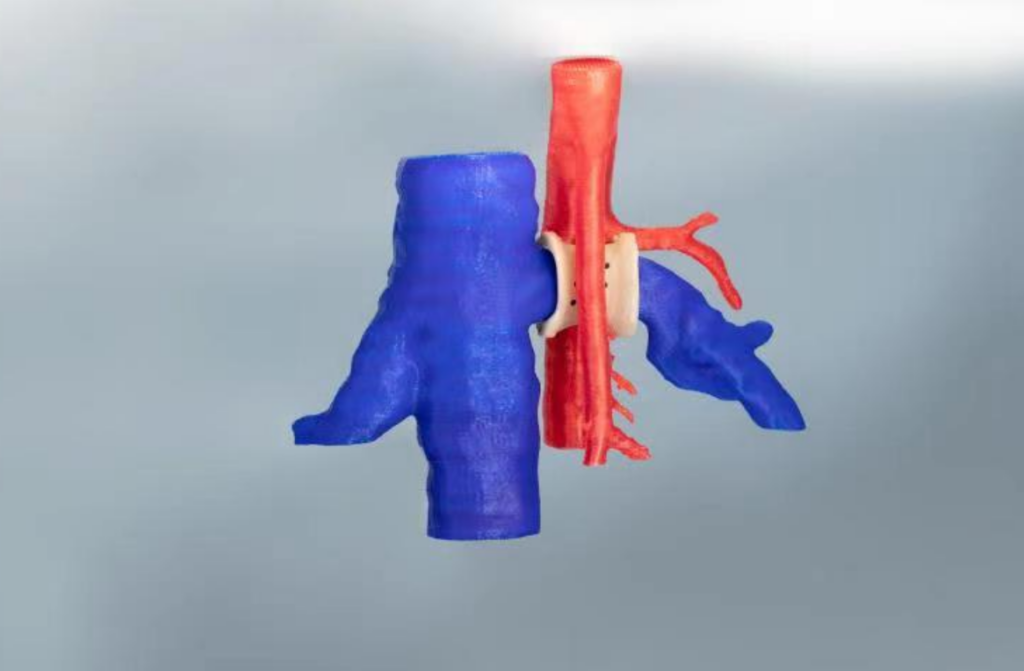

In 2018, the Department of Urology at Tangdu Hospital and the 3D Printing Research Center of the Air Force Medical University jointly performed the world’s first surgery treating nutcracker syndrome with 3D printing technology, adopting PEEK human bionic material to make the human implants.

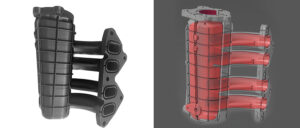

Nutcracker PEEK implant 3D printed by INTAMSYS equipment

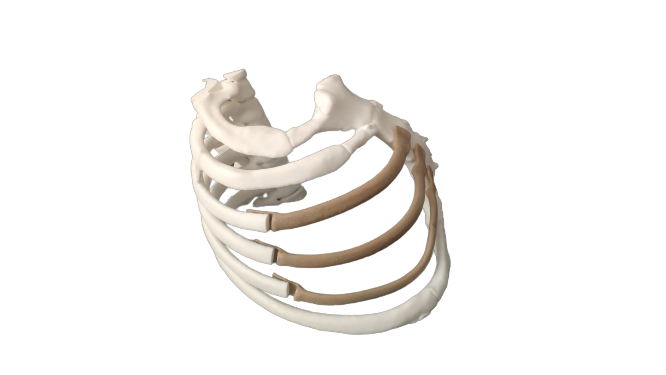

The 3D Printing Research Center of the Air Force Medical University made breakthroughs in several thoracic rib PEEK replacement surgeries by creating new implants with the help of the FDM/FFF 3D printing technology of INTAMSYS.

PEEK thoracic rib implant 3D printed with INTAMSYS FUNMAT PRO 610

Hundreds of PEEK implant procedures have already been performed with the help of 3D printing technology, and the patients recovered well after the operation.

3D printing technology unleashes new potential of PEEK materials

As the medical implant production switches from the conventional standard mass production to patient-specific customized implant production, 3D printing is taking on an increasingly important role in the medical implant manufacturing industry, making it possible to realize batch production of patient-specific and small-scale customized PEEK implants.

FDM/FFF 3D printing technology based on material extrusion process is one of the more economical and efficient production approaches for small-batch production compared with the traditional manufacturing approaches. For example, in the aforementioned skull reconstruction surgery at Tangdu Hospital, the medical team “tailored” PEEK implants for the patient based on the FDM/FFF 3D printing technology of INTAMSYS, and the skull pieces were perfectly embedded with the patient’s natural bone, contributing to quick post-operative recovery.

Taking the advantages of additive manufacturing/3D printing technology in fabricating complex structures, the bioactivity of PEEK materials can be improved at the design level. For example, 3D printing technology can construct interconnected and integrated porous structures to facilitate osseointegration of PEEK implants, improve x-ray accuracy, and achieve elastic modulus that closely matches human cancellous bone.

PEEK Filament

Challenges of PEEK FDM/FFF 3D printing

The manufacturing equipment and process stability are the prerequisites for the commercialized application of PEEK 3D printed medical implants. Due to its high melting point, PEEK requires high-temperature heat treatment. The combination of elevated processing temperatures and the high crystallization rate of PEEK leads to excessive thermal stress (uneven distribution between printed layers) and may result in thermal cracking, as well as poor interlayer adhesion and warpage in 3D printed PEEK parts. Therefore, PEEK FDM/FFF 3D printing is far more complex and challenging than the processes using engineering and general purpose plastics. In order to develop high-quality PEEK 3D printed parts, specialized manufacturing techniques, as well as FDM 3D printing equipment dedicated to PEEK materials, are required.

In essence, the 3D printing of high performance materials is a thermal processing of polymer materials. The thermal design of the chamber of the 3D printing equipment and the suitable chamber temperature will enhance the bonding strength between layers of polymer materials, while reducing the shrinkage and deformation due to cooling and residual stress. Different materials have different requirements for chamber temperature during the material extrusion 3D printing process, and the chamber temperature required for 3D printing of high-performance PEEK materials should achieve 150-250°C.

Taking INTAMSYS FUNMAT PRO 610HT 3D printing equipment for high-performance materials as an example, it has a fully enclosed molding chamber, the temperature of the 3D printing platform and the chamber can be controlled in a range from room temperature to 300°C, the equipment controls the heating of the chamber through the double-side circulation hot duct while synchronously heating the printing bed, which is equipped with thickened insulation layer externally to reduce heat dissipation. After reaching the preset temperature and stabilizing for a period of time, the temperature field inside the whole chamber is highly homogeneous, with the temperature controlled accurately within the range of 300°C ± 2.5%. Due to its excellent high temperature performance, INTAMSYS FUNMAT PRO 610HT 3D printing equipment is mainly used for additive manufacturing with high value-added materials such as PEEK, ULTEM and PPSU, and meets the 3D printing requirements of most FDM/FFF materials in the market. Unlike ordinary 3D printers that are heated only by the printing platform, FUNMAT PRO 610HT can further ensure that the first layer of 3D printed parts maintains a high-strength adhesion with the printing platform, and the material is heated at a uniform temperature in all parts during the 3D printing process, which facilitates large-size sample molding while preventing warping and other defects, providing a reliable guarantee for high-quality 3D printing of PEEK materials.

Whether it is for the treatment of skull, sternum or nutcracker syndrome, customized implant protocols will be more precise and efficient to provide a better treatment experience and recovery for patients. And the 3D printing technology also keeps on providing more innovations and breakthroughs in other medical areas such as bone reconstruction and prosthesis manufacturing. We firmly believe that the medical world in the future will be witnessing infinite possibilities brought by 3D printing technology.